Home | Steel Grating

Steel grating introduction to help you better understand it

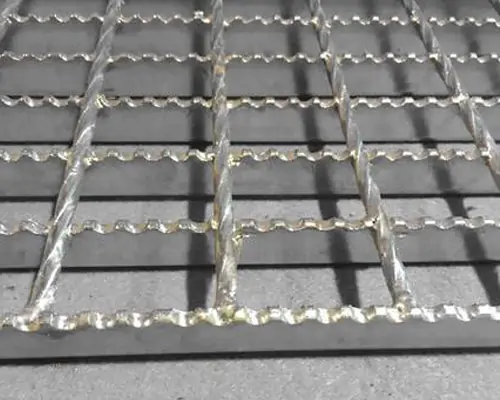

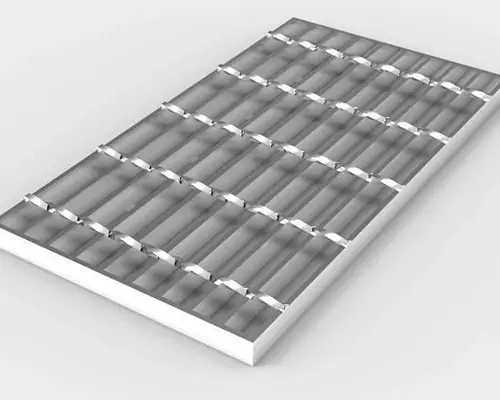

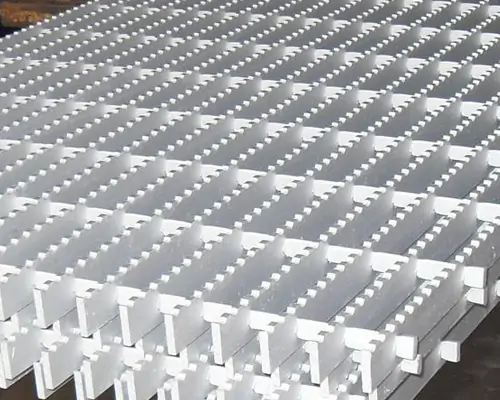

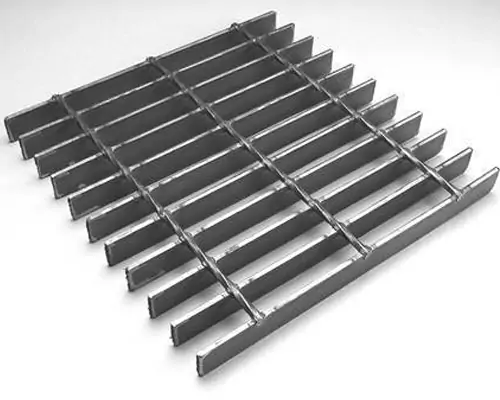

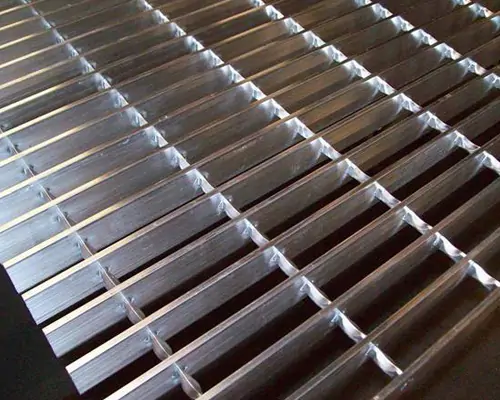

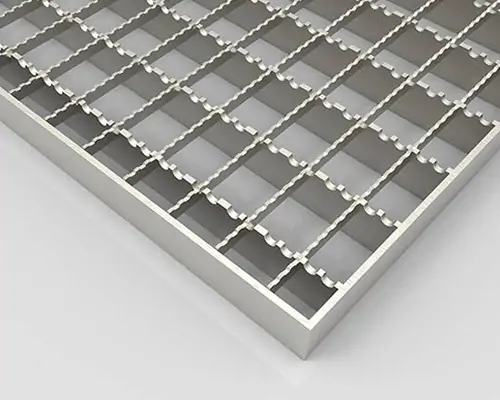

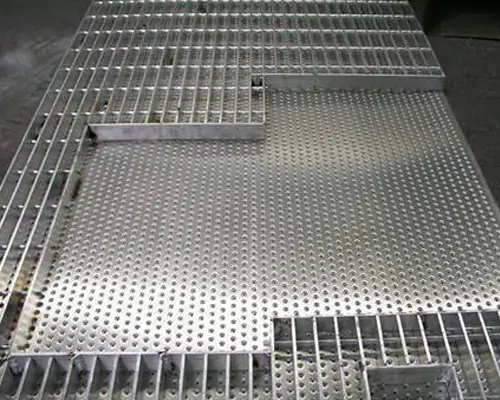

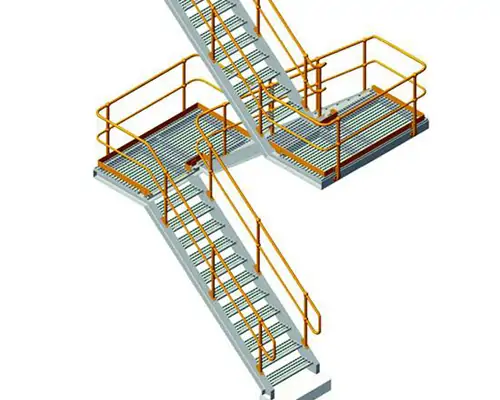

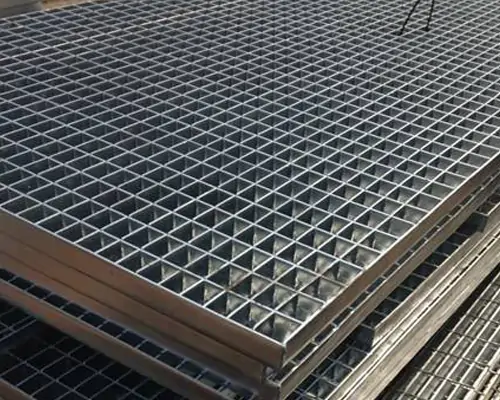

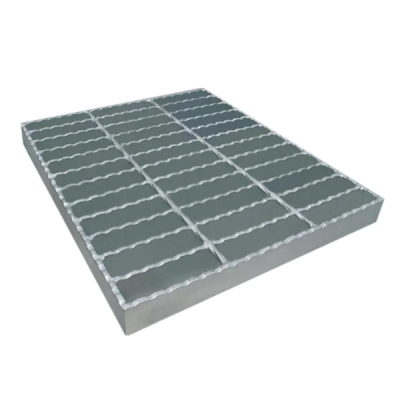

Steel grating, also known as bar grating or metal grating, is an open grid assembly of metal bars, in which the bearing bars, running in one direction, are spaced by rigid attachment to cross bars running perpendicular to them or by bent connecting bars extending between them, which is designed to hold heavy loads with minimal weight. It is widely used as floors, mezzanines, stair treads, fencing, trench covers and maintenance platforms in factories, workshops, motor rooms, trolley channels, heavy loading areas, boiler equipment and heavy equipment areas, etc.

- High strength and firm structure.

- High anti-slip performance.

- High load capacity and resistance to deformation.

- Anti-press.

- Explosion proof.

- Light weight.

- Various styles and sizes for choice.

- Good ventilation and heat resistance.

- Alkali and acid resistance.

- Harsh environment resistance.

- Corrosion and rust resistance.

- Easy installation.

- Durable and long service life.

- MaterialCarbon steel, aluminum steel, stainless steel.

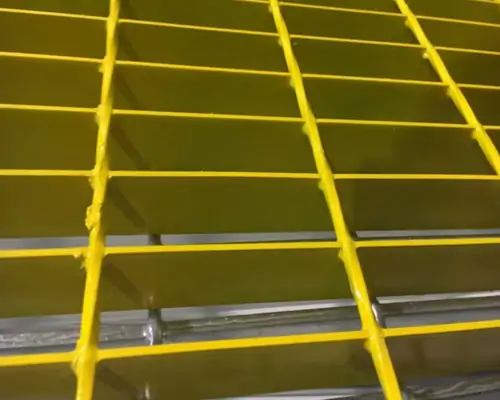

- Surface treatmentGalvanized, mill finished, painted, powder coated, PVC coated.

- Surface typeStandard plain surface, serrated surface.

- Common bearing bar spacing7/16″, 1/2″, 11/16″, 15/16″, 19/16″ in 1/16″ increments.

- Common cross bar spacing2″, 4″ in 1″ increment.

- Bearing bar depth3/4″ to 7″.

- Bearing bar thickness1/8″ to 1/2″.

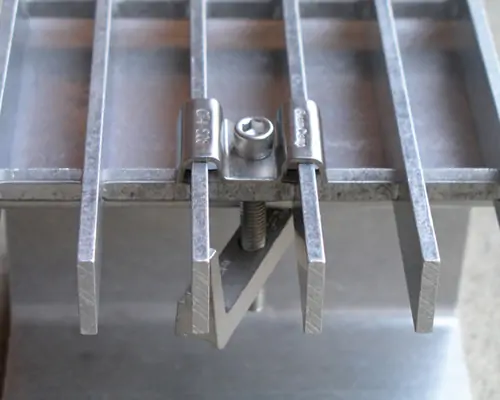

A special bent-clip type fastener for removable bar grating panels.Bent clips bridging two bearing bars are available in galvanized steel, stainless steel, or aluminum.

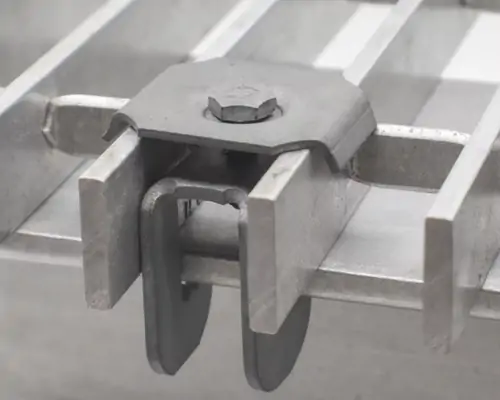

Mechanical fasteners installed from the top surface of the grating create a friction connection with the flange supporting the panel.“G” clips are easily installed without drilling or welding.

Grating can be connected by one man only, working from above, without the need to drill the steel or weld on site.

Plates, punched with holes and welded between the bearing bars, facilitate bolting to the supporting structure.

Narrow formed clip captures one bearing bar when spacing is limited, They are especially helpful in holding down riveted grating.

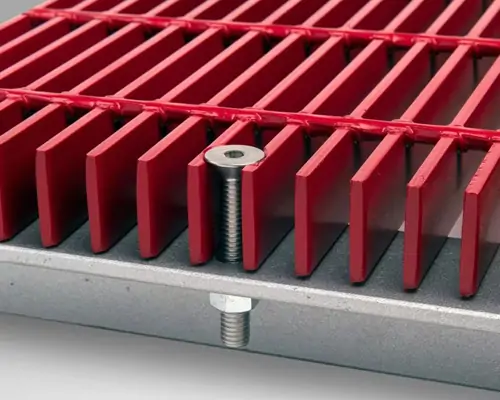

The narrow spacing of close mesh grating allows for countersinking or milling of the bearing bars to support bolt shoulders. It is available for aluminum grating only.

Applications

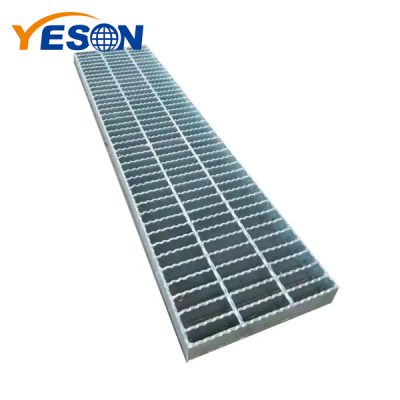

Stair tread.

Floor.

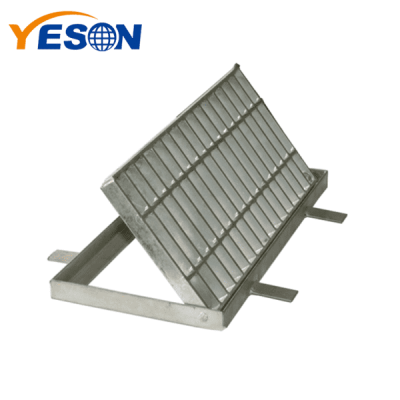

Sun visor.

Tree cover.

Bridge construction.

Chair.

Baby carriage.

Food panel.

Walkway.

Showcase ground.

Fountain panel.

Trench cover.

Decorative wall.

Shelve.

Substation fire pit.

Optional platform.

Ceiling.

Ramp.

Drainage cover.

Security fence.

Stand.

Clean area panel.

Catwalk stage.

Window.

Lifting track.

Industrial truck.

Transformer reservoir.

Observation tower.

Split obstacle or screen.

It has great corrosion-resistant, shiny surface appearance and good ventilation and is widely used in the petrochemical industry, power plants and sewage treatment plants.

It comes in a variety of colors, which can be selected to match the device according to your needs.

It has the most excellent corrosive resistant among all steel gratings and is especially suitable for various strong corrosive environments.

It is lighter in weight without compromising to the load capacity and mechanical strength and is mainly used for platform ceilings and outdoor curtain walls.

It consists of bearing bars that are automatically resistance-welded with the cross bars via precise use of intense heat and pressure.

It relies on employing enormous hydraulic pressure that fuses the two close-tolerance slotted bars together.

It is manufactured by inserting cross bars into pre-punched holes in the bearing bar and then cross bars are swaged forming a positive mechanical connection.

It has high load capacity, anti-slip surface to be used in heavy traffics as platforms, walkways as well as bride decking.

It is one of the most popular and versatile industrial steel gratings.

It provides light weight yet high strength and load capacity.

It is widely used in outdoors, such as:sunshade and building facade.

It provides excellent bearing capacity and is widely used in almost all industrial applications.

It provides excellent slip resistance and is especially applicable to places where excellent slip resistance is required.

It is easily fabricated and provides a high load structure and is widely used as steel grating platform, walkway, bridge decking and flooring.

It supplies far greater strength-to-weight ratio than other flooring materials to bear the heavy load such as forklift or truck traffic.

It has closer bearing bar spacing less than 25 mm. It is mainly used in the occasion have higher request for gratings.

More Steel / Metal Grating Solutions

Product Category

- 358 Mesh Fence (7)

- Wire Mesh Series (32)

- Farm Fence (7)

- Welded Wire Mesh (9)

- Hexagonal Wire Mesh (3)

- Crimped Wire Mesh (2)

- Decorative Mesh (10)

- Stainless Steel Mesh (1)

- Mesh Fence Products (28)

- Chain Link Fence (4)

- Garden Fence (8)

- Security Fence (5)

- Silt Fence (1)

- Temporary Fence (5)

- Wrought Iron Fence (7)

- Hardware Accessory (21)

- Wire Series (3)

- Bird Spike (1)

- Fence Post (6)

- Nail Series (4)

- Other Accessory (7)

- Filter Mesh Series (7)

- Barbed Wire (7)

- Gabion Barriers (6)

- Mesh Sheet (5)

- Metal Cages (8)

- Expanded Metal Mesh (3)

- Perforated Metal Mesh (5)

- Plastic Mesh and Shade Net (3)

- Pest Control (1)

- Steel Grate (2)

- Window Screen Series (6)

Showing all 2 results

YESON Happy Clients

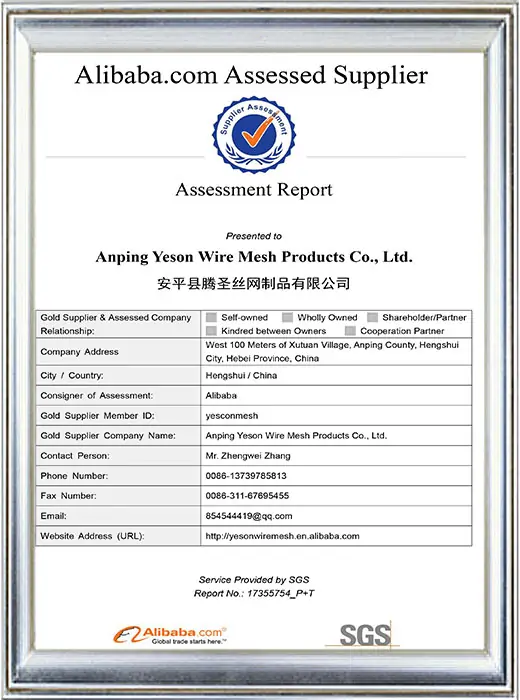

Since 1998, YESON has served clients in over 70 countries and regions. It’s growing business partnerships and also friendships with our clients. Contact our specialists for any wire mesh solution.

FAQs

Q1: Are you a real factory? Or a trading company?

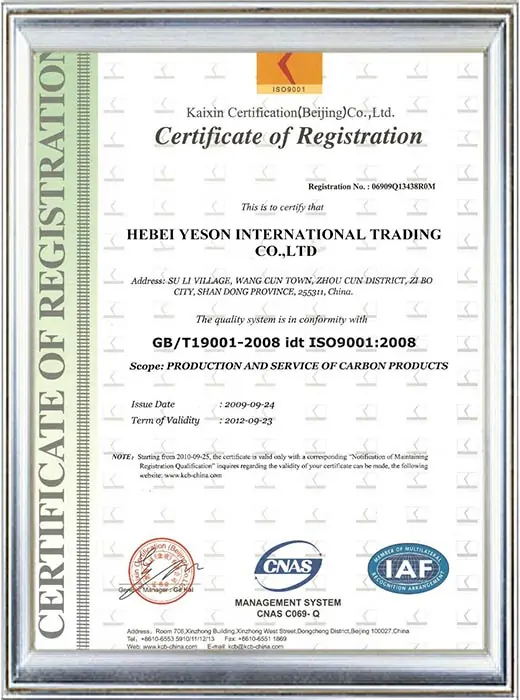

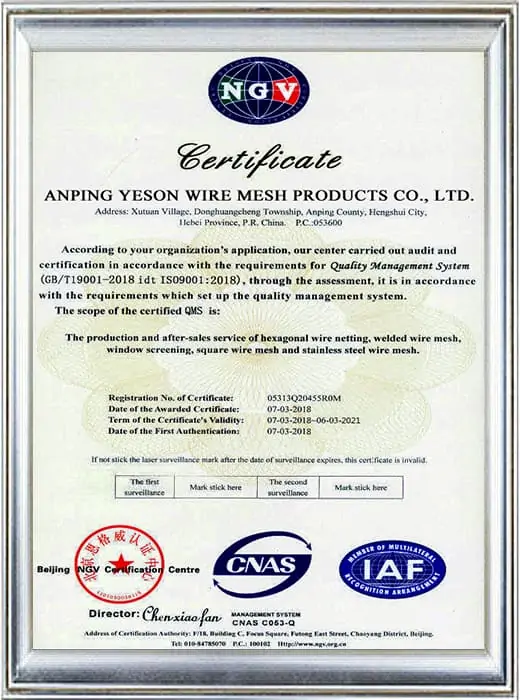

A: Yes, we have been in providing the products in this field for 20+ years.We have both real factory ( Anping Yeson Wire Mesh Products Co.,Ltd ) and trading company( Hebei YESON International Trade Co., Ltd ), mainly produce and sell metal mesh products.

Q2: Can I have a sample to check first?

A: Yes, we do offer raw materials samples or small trail sample order for you to check. Just tell our specialists of the details and they’ll help you about it.

Q3: Can I come to China for Factory inspection?

A: Of course, you are much welcome to visit our factory and offices. Now we also support using ZOOM or WeChat for online factory inspection.

Q4: Can you design and make as customers' request?

A: We support customization requirements from customers and provide corresponding solutions and services.

Q5: Can I get a lower price if I make a large order?

A: Of course, cheaper price with large order.

Q6: If the quality is not met my request, how do you solve this problem?

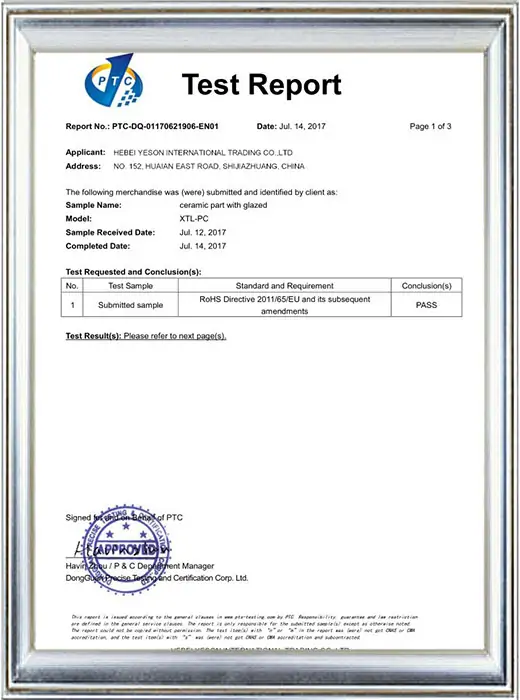

A: First of all, we don’t allow any defective products to leave our factory.We do strict quality inspection in every step. But if there is any problem, we will guarantee to solve it within 2 working days after your pictures or videos proof.

Q7: Do you have quality guaranteed?

Q8: How do we ship the goods?

A:We will quote you the ocean freight, if the goods is not large, it will be loaded by air freight or Express. No matter any ways of transportation, our forwarders will provide professional service to ensure the goods arrives at your place smoothly.

Q9: What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the courier cost. And all the sample cost will be refunded after you place the order.

Get A Quote Today!

Have a look at how some of our clients perceive our goods and services: