Dutch Woven Stainless Steel Wire Mesh

- Product Name: Stainless Steel Wire Mesh

- Size: Customizable

- Main materials: 201, 304, 304L, 316, 316L, with special options including nickel, nickel-chromium alloys, titanium, 430, etc.

- Weaving methods: Plain weave, twill weave, Dutch weave, herringbone weave, etc.

- Mesh count: Ranges from 0.5 mesh to 600 mesh (plain/twill) to 2300 mesh (Dutch weave), customizable according to requirements.

- Wire diameter: 5mm to 0.025mm

- Width: Standard widths are 1 meter, 1.13 meters, 1.22 meters, with special options available from 1.5 meters to 2.6 meters.

- Length: Standard length is 30 meters, customizable according to requirements.

- Services: We can provide samples, inform customers of the progress by taking photos and recording videos during production to reassure customers, and update customers on market trends from time to time.

Product Details

Product Description

Stainless steel wire mesh is meticulously crafted from high-quality stainless steel wire, intricately woven to create square or oblong openings. Renowned for its exceptional resistance to rust, corrosion, acids, alkalis, heat, and chemicals, stainless steel woven wire mesh embodies durability and strength.

With its robust properties, stainless steel woven wire mesh finds widespread applications across industries, architecture, residences, and various other settings. Whether it’s for industrial filtration, architectural design elements, or enhancing residential spaces, stainless steel woven wire mesh stands as a reliable and versatile solution.

Note: Whether in color or size, Anping YESON offers customization services. Besides, if you have any requirements for packaging, we will try our best to meet them. Please send us your real requirements and get the products to your satisfaction.

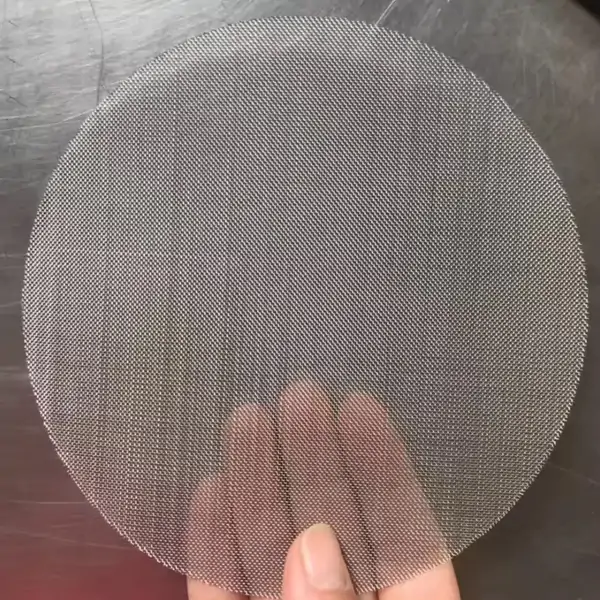

Product Show

Product Specification

| Mesh / inch | Wire Dia. mm | Aperture mm | Mesh / inch | Wire Dia. mm | Aperture mm |

| 2 | 1.8 | 10.9 | 100 | 0.1 | 0.154 |

| 3 | 1.6 | 6.866 | 120 | 0.08 | 0.132 |

| 4 | 1.2 | 5.15 | 140 | 0.07 | 0.111 |

| 5 | 0.91 | 4.17 | 150 | 0.065 | 0.104 |

| 6 | 0.8 | 3.433 | 160 | 0.065 | 0.094 |

| 8 | 0.6 | 2.575 | 180 | 0.053 | 0.088 |

| 10 | 0.55 | 1.99 | 200 | 0.053 | 0.074 |

| 14 | 0.5 | 1.314 | 250 | 0.04 | 0.061 |

| 18 | 0.45 | 0.961 | 325 | 0.035 | 0.043 |

| 20 | 0.4 | 0.87 | 350 | 0.033 | 0.0395 |

| 30 | 0.305 | 0.542 | 400 | 0.03 | 0.0335 |

| 50 | 0.2 | 0.308 | 500 | 0.025 | 0.0258 |

| 60 | 0.19 | 0.223 | 600 | 0.018 | 0.023 |

| 70 | 0.14 | 0.223 | |||

| 80 | 0.12 | 0.198 | |||

| 90 | 0.11 | 0.172 |

| Plain weave mat net | ||||

| Filter mesh number | Mesh Count (Warp x Weft) | Wire Diameter (Warp x Weft) | Aperture Size (um) | Weight per Square Meter (kg) |

| 32# | 8 x 62 | 0.63mm x 0.45mm | 300 | 5.42 |

| 40# | 10 x 79 | 0.50mm x 0.355mm | 250 | 3.16 |

| 48# | 12 x 64 | 0.58mm x 0.40mm | 280 | 2.9 |

| 55# | 14 x 88 | 0.40mm x 0.30mm | 180 | 2.54 |

| 76# | 19 x 140 | 0.315mm x 0.20mm | 140 | 1.88 |

| 80# | 20 x 300 | 0.35mm x 0.20mm | – | 3.6 |

| 95# | 24 x 110 | 0.355mm x 0.25mm | 120 | 2.45 |

| 100# | 25 x 140 | 0.28mm x 0.20mm | 100 | 1.95 |

| 120# | 30 x 150 | 0.25mm x 0.18mm | 80 | 1.68 |

| 140# | 35 x 175 | 0.224mm x 0.16mm | 71 | 1.52 |

| 160# | 40 x 200 | 0.20mm x 0.14mm | 60 | 1.4 |

| 180# | 45 x 250 | 0.16mm x 0.112mm | 56 | 1.09 |

| 200# | 50 x 250 | 0.14mm x 0.11mm | 53 | 1.04 |

| 220# | 55.5 x 280 | 0.14mm x 0.10mm | 50 | 0.92 |

| 240# | 65 x 330 | 0.11mm x 0.08mm | 36 | 0.71 |

| 280#(1) | 70 x 350 | 0.11mm x 0.08mm | 35 | 0.72 |

| 280#(2) | 70 x 385 | 0.11mm x 0.07mm | 32 | 0.75 |

| 300# | 78 x 700 | 0.11mm x 0.08mm | 30 | 1.39 |

| 315#(1) | 80 x 400 | 0.10mm x 0.065mm | 40 | 0.62 |

| 315#(2) | 80 x 600 | 0.10mm x 0.06mm | – | – |

| 315#(3) | 80 x 800 | 0.15mm x 0.04mm | – | – |

| 320# | 81 x 780 | 0.10mm x 0.07mm | 30 | 1.22 |

| 354# | 90 x 550 | 0.12mm x 0.05 | – | – |

| Twill Weave Mat Type Mesh | ||||

| Filter mesh number | Mesh Count (Warp x Weft) | Wire Diameter (Warp x Weft) | Aperture Size (um) | Weight per Square Meter (kg) |

| 360# | 91 x 787 | 0.10mm x 0.07 | 25 | 1.24 |

| 400# | 101 x 900 | 0.10mm x 0.063 | 20 | 1.22 |

| 472# | 120 x 400 | 0.10mm x 0.075 | – | – |

| 500# | 127 x 1100 | 0.07mm x 0.05 | 17 | 0.81 |

| 630# | 160 x 1500 | 0.063mm x 0.04 | 15 | 0.62 |

| 650#(1) | 165 x 400 | 0.071mm x 0.06 | – | – |

| 650#(2) | 165 x 600 | 0.071mm x 0.05 | – | – |

| 650#(3) | 165 x 800 | 0.071mm x 0.05 | 25 | – |

| 650#(4) | 165 x 1100 | 0.071mm x 0.045 | – | – |

| 650#(5) | 165 x 1400 | 0.071mm x 0.04 | 16 | 0.76 |

| 685# | 174 x 1700 | 0.063mm x 0.032 | 13 | 0.61 |

| 787#(1) | 200 x 600 | 0.071mm x 0.06 | – | – |

| 787#(2) | 200 x 800 | 0.071mm x 0.06 | – | – |

| 787#(3) | 200 x 1400 | 0.071mm x 0.04 | 12 | 0.8 |

| 795# | 202 x 1760 | 0.05mm x 0.032 | 10 | 0.6 |

| 850# | 216 x 1860 | 0.045mm x 0.030 | 9 | – |

| 1000# | 254 x 2000 | 0.04mm x 0.028 | 8 | 0.5 |

| 1125# | 285 x 2235 | 0.036mm x 0.025 | 7 | – |

| 1228# | 312 x 2100 | 0.035mm x 0.025 | – | – |

| 1250# | 318 x 2235 | 0.036mm x 0.025 | – | – |

| 1280# | 325 x 2300 | 0.035mm x 0.025 | 5 | 0.45 |

| 1575# | 400 x 3100 | 0.035mm x 0.019 | 3 | – |

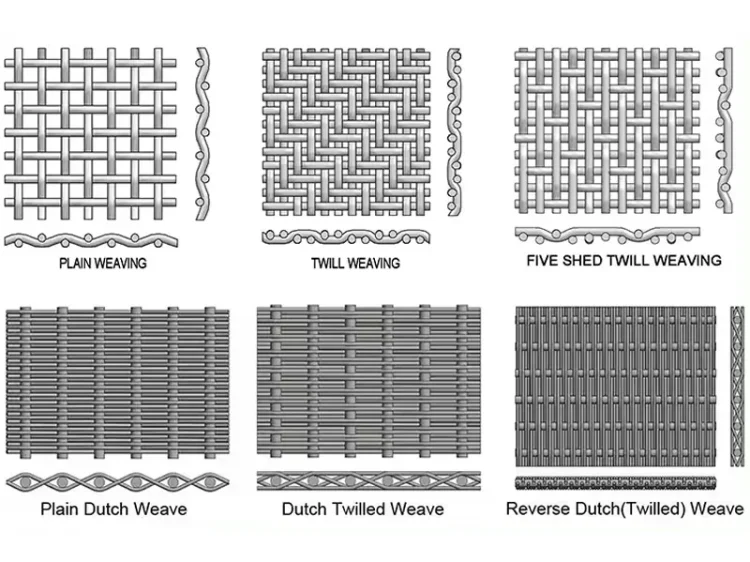

Weaving Method

Plain weave: The most popular method in industrial production and civil life, widely utilized for various purposes.

Twill weave: Mainly used for weaving Galvanized Steel Wire Mesh with mesh counts ranging from 150 to 600 and wire diameter of 0.3mm.

Dutch weave: Known for its excellent tensile strength, primarily employed in weaving Galvanized Steel Wire Mesh with a wire diameter of 0.3mm, ideal for liquid and slurry filtration.

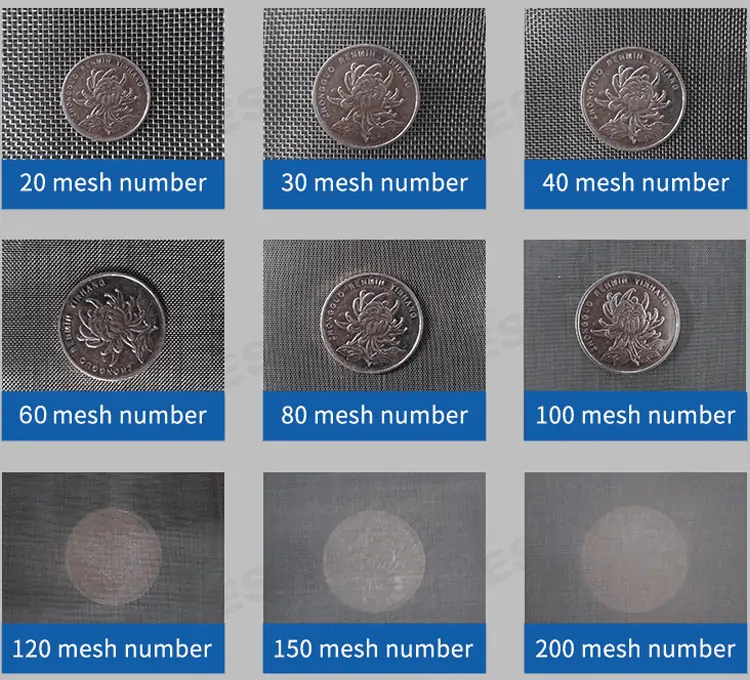

Mesh Number Display

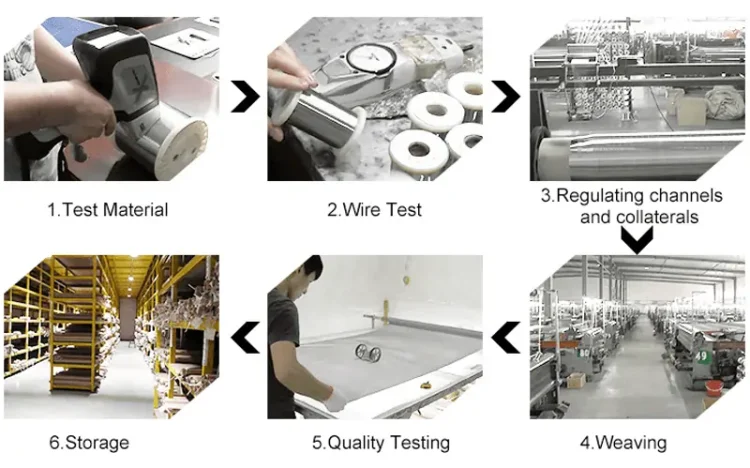

Product Process

Product Application

Stainless steel wire mesh is utilized for screening and filtering under acidic and alkaline environmental conditions, serving various industries. It is employed in the petroleum industry for mud filtration, in the chemical and chemical fiber industries for sieve filtration, and in the electroplating industry for acid washing screens. Furthermore, it finds application in filtering various particles, including foam particles, paper mill particles, plastic particles, rubber particles, and non-woven fabric particles.

Industries Served:

This versatile material finds extensive applications in a wide range of industries, including but not limited to:

- Chemical fiber spinning

- Short fiber and ultra-fine fiber processing

- Leather and non-woven fabric production

- Plastic granulation and extrusion (PVC, PE, PP, ABS, PS, etc.)

- Masterbatch production

- Rubber processing

- Aerospace and aviation

- Petrochemical

- Mining

- Food and pharmaceuticals

- Machinery manufacturing

- Hydraulic systems

- Automotive

- New energy generation

Specific Applications:

- Filtration of petroleum mud and sand control pipes

- Filtration of plastic and rubber particles

- Filtration components for various chemical fiber spinning machines, leather and non-woven fabric equipment, and twin-screw extruders

- Hydraulic filter elements

- Battery collectors (titanium mesh, nickel mesh)

- Screening and filtration in food and pharmaceutical industries

- Indoor decoration, protection, and shielding

- Manufacturing of headphone mesh, button batteries, and speaker components.

Packaging & Shipping

Package:

1. inside use carton pipe for support+wire mesh layer+water proof paper ;

2. outside use plastic wooden bags, +wooden case/carton pipes/wooden carton.

Shipping:

▲International Express: Applicable to samples and trial orders, the price is moderate, about 5-7 days to arrive.

▲Air transportation: Suitable for emergency delivery, the price is more expensive, arrives in about 12-15 days.

▲Sea transportation: Suitable for non-emergency delivery, the price is more cheap, arrives in about 30-45 days.

Supplier Profile:

Anping Yeson Wire Mesh Products Co., Ltd. is a leading manufacturer and supplier of wire mesh products based in China. With over 30 years of experience in the industry, we have established ourselves as a trusted provider of high-quality fencing solutions and wire mesh products.

Our product range includes a variety of fencing options such as 358 Anti Climb Fence, Temporary Fence, Chain Link Fence, BRC Fence, Wrought Iron Fence, Crowd Control Barrier, Razor Wire, and Fence Accessories. Additionally, we offer a wide range of wire mesh products including Gabion Mesh, Defensive Barrier, Hexagonal Mesh, Welded Mesh, Window Screens, Crimped Wire Mesh, Plastic Netting, Geogrid, and Wire Mesh Containers.

We take pride in our commitment to quality, timely delivery, and excellent customer service. Our products are manufactured using the latest technology and highest quality materials to ensure durability and reliability. With our extensive experience and expertise, we cater to customers both domestically and internationally, serving markets in Hong Kong, Europe, the United States, Southeast Asia, the Middle East, and Africa.

At Yeson Wire Mesh, we are dedicated to providing innovative solutions and superior products to meet the diverse needs of our customers. Whether you require standard fencing solutions or customized wire mesh products, we have the capabilities to deliver. Contact us today to learn more about our products and services.

Product categories

- 358 Mesh Fence (9)

- Farm Fence (7)

- Welded Wire Mesh (9)

- Hexagonal Wire Mesh (3)

- Crimped Wire Mesh (2)

- Decorative Mesh (10)

- Stainless Steel Mesh (1)

- Chain Link Fence (4)

- Garden Fence (8)

- Security Fence (5)

- Silt Fence (1)

- Temporary Fence (5)

- Wrought Iron Fence (7)

- Wire Series (3)

- Bird Spike (1)

- Fence Post (6)

- Nail Series (4)

- Other Accessory (7)

- Filter Mesh Series (7)

- Barbed Wire (7)

- Gabion Barriers (6)

- Mesh Sheet (5)

- Metal Cages (8)

- Expanded Metal Mesh (3)

- Perforated Metal Mesh (5)

- Plastic Mesh and Shade Net (3)

- Pest Control (1)

- Steel Grate (2)

- Window Screen Series (6)

- Wire Mesh Container (5)