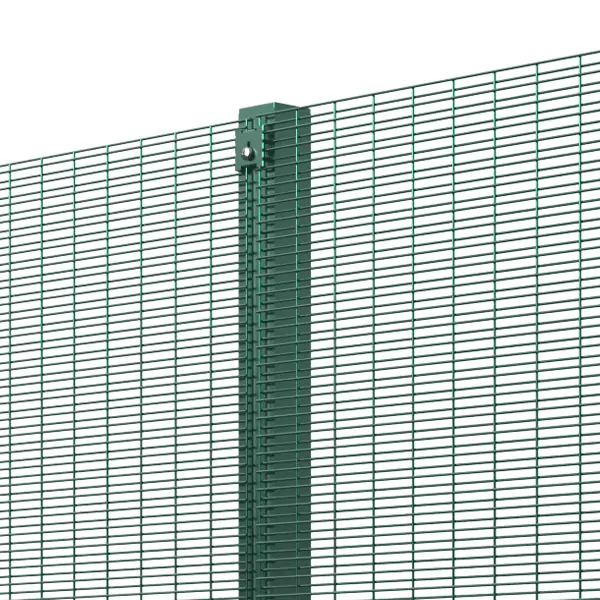

Our Welded Wire Fence Panel is a premium solution for securing and enhancing the perimeter of your property. Crafted with precision and durability in mind, this fence panel offers unbeatable protection while adding aesthetic appeal to any environment.

Table of Contents

ToggleType of Welded Wire Fence Panel

When it comes to safeguarding properties, the versatility of a welded wire fence panel comes into play, offering a singular solution tailored to various needs. Here’s a breakdown of the primary type:

1. Standard Welded Wire Fence Panel:

Characterized by its straightforward design, the standard welded wire fence panel serves as a foundational option for securing residential, commercial, and industrial properties alike. Its uniform mesh pattern, typically featuring square or rectangular openings, ensures both security and visibility.

Material Composition

A welded wire fence panel is crafted from a combination of high-quality materials, carefully selected to ensure strength, durability, and longevity. The key components of our welded wire fence panel include:

Steel Wire: The fence panel is primarily constructed using steel wire, known for its robustness and resilience. Steel wire provides the structural integrity needed to withstand external forces and environmental conditions.

Galvanized Coating: To bolster corrosion resistance and extend the lifespan of the fence panel, steel wire frequently undergoes treatment with a galvanized coating. This protective layer serves as a formidable barrier against rust, guaranteeing that the panel maintains its sturdiness and reliability, even in the harshest climates.

Welding Rods: The assembly of our welded wire fence panel involves welding individual wire strands together using specialized welding rods. These rods, typically made from alloy steel, facilitate the welding process and contribute to the overall strength and stability of the panel.

Optional Finishes: Depending on your preferences and requirements, our welded wire fence panel may feature optional finishes such as powder coating or vinyl coating. These finishes not only add a decorative touch but also provide additional protection against corrosion, abrasion, and fading.

Versatile Applications

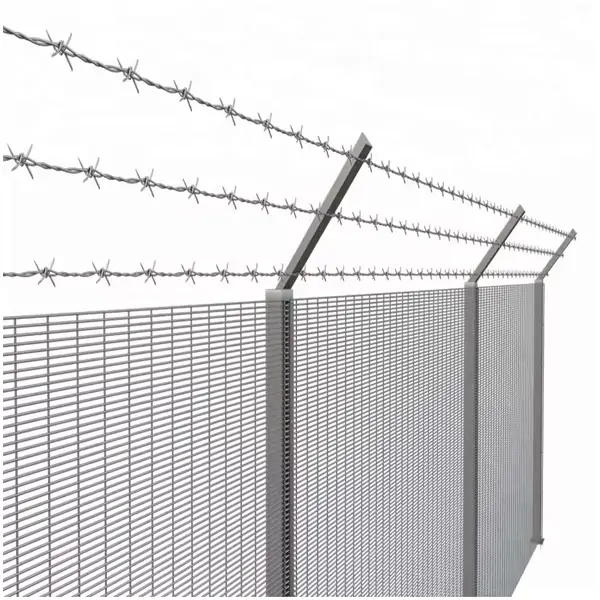

Suitable for various environments including residential, commercial, and industrial settings, our welded wire fence panel offers versatile solutions. It can be used to secure gardens, yards, perimeters, or construction sites effectively.

Benefits of welded wire fence panel

Superior Strength: Constructed from high-quality steel wire, our welded wire fence panel offers exceptional strength and durability. It withstands harsh weather conditions and resists bending or warping, ensuring long-lasting performance.

Tight Mesh Design: The tightly welded mesh pattern provides a strong barrier against intruders while maintaining visibility. This design deters unauthorized access without compromising on the aesthetics of your property.

Easy Installation: Designed for hassle-free installation, our fence panel comes with pre-drilled holes for quick and convenient mounting. Whether you’re a DIY enthusiast or a professional installer, setting up our welded wire fence panel is a breeze.

Low Maintenance: Our welded wire fence panel requires minimal maintenance, saving you time and effort in the long run. It is resistant to rust, corrosion, and UV damage, ensuring it retains its structural integrity and appearance over time.

Customizable Options: Available in various sizes, heights, and finishes, our welded wire fence panel can be tailored to meet your specific requirements. Choose from galvanized, powder-coated, or vinyl-coated finishes to match your aesthetic preferences.

Common Issues with Welded Wire Fence Panels

1. Corrosion and Rust: One common problem encountered with welded wire fence panels is the development of corrosion and rust over time, especially when exposed to harsh weather conditions. This deterioration not only affects the appearance of the panels but also compromises their structural integrity, potentially leading to weak spots or breaches in the fence line.

2. Weld Failure: Another issue that may arise is weld failure, where the welds securing the wire mesh together weaken or break. This can occur due to poor welding techniques during manufacturing or excessive stress on the panels. Weld failure can result in areas of weakness or even complete panel failure, compromising the security of the fenced area.

3. Mesh Distortion: Heavy impact or pressure on the fence panels can cause the wire mesh to become distorted or bent out of shape. This can occur from accidental collisions, vandalism, or leaning against the fence. Mesh distortion not only detracts from the aesthetic appeal of the fence but also reduces its effectiveness in containing or deterring intruders.

4. Installation Challenges: Improper installation practices or inadequate support can lead to installation-related issues such as unevenness or instability in the fence line. This may result in gaps, leaning sections, or areas where the fence is not properly secured to the ground. Addressing installation challenges promptly is crucial to maintaining the security and integrity of the fence.

5. Maintenance Requirements: While welded wire fence panels are relatively low-maintenance, they still require periodic upkeep to ensure optimal performance and longevity. Neglecting routine maintenance tasks such as cleaning, inspecting for damage, and applying protective coatings can accelerate deterioration and compromise the durability of the panels over time.

Our Welded Wire Fence Panel is the ultimate solution for securing and enhancing your property. With its superior strength, tight mesh design, and versatile applications, it provides unmatched protection and aesthetic appeal. Invest in our welded wire fence panel today and enjoy peace of mind knowing your property is well-protected.