Table of Contents

ToggleWhat is Black Wire Cloth Filter Screen?

Black Wire Cloth Filter Screen is a material used for filtration and screening, usually made of synthetic fibers such as polyester or polypropylene, with a fine mesh structure. It can filter air, liquids, or solid particles, and has functions of adsorption, filtration, and separation of impurities. Black Wire Cloth Filter Screen is commonly used in air conditioners, air purifiers, water treatment equipment, automotive engine air filters, and other fields to improve environmental quality and product quality.

Types of Black Wire Cloth Filter Screen

The types of Black Wire Cloth Filter Screen usually include two categories:

one is woven from steel wire, known as black wire cloth; the other is made from synthetic fiber materials, known as black mesh fabric. Black wire cloth woven from steel wire typically boasts high strength and durability, suitable for demanding filtration and screening applications. On the other hand, black mesh fabric made from synthetic fibers offers excellent softness and elasticity, often employed in light-duty filtration and screening tasks. The choice between the two types depends on specific application requirements and performance needs.

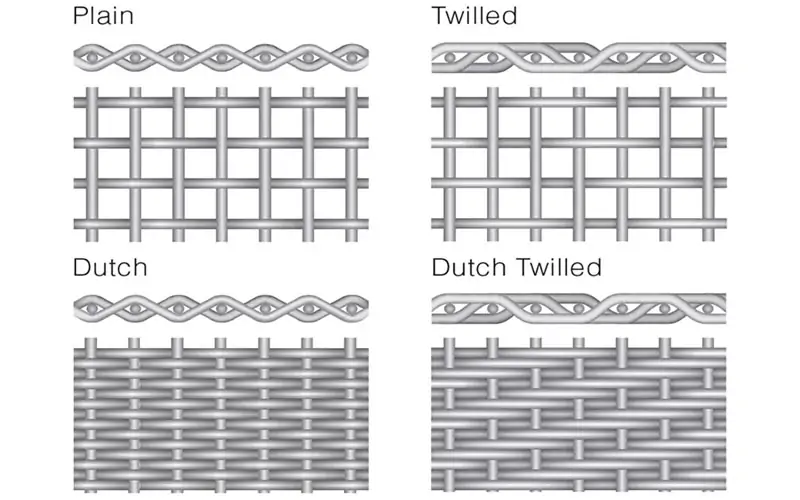

Weave style: plain weave, twill weave, herringbone weave, dutch weave.

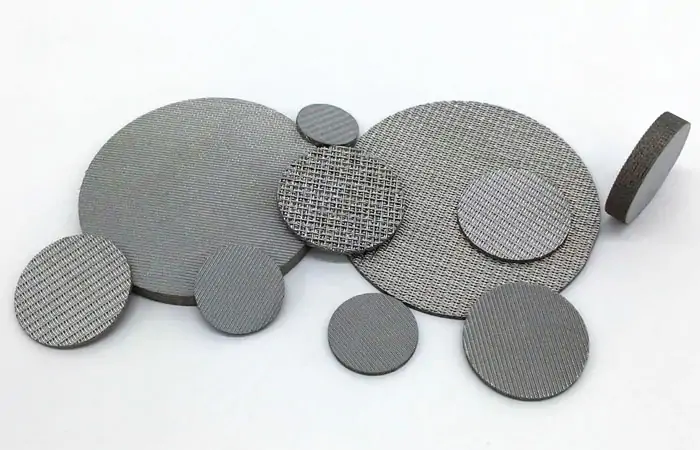

Disc shape: round, rectangle, square, oval, circular, cap, cone, tube, bowl, waist and abnormity, etc.

Layer: single layer or multilayers.

Choose a Professional Manufacturer of Black Wire Cloth Filter Screens

When selecting a professional manufacturer of black wire cloth filter screens, there are several key factors to consider:

Experience and Reputation

Technical Capability

Customization Capability

Quality Control

After-Sales Service

As a reliable manufacturer of black wire cloth filter screens in China, YESON can provide you with high-quality black wire cloth. You can also request custom sizes. If you have any questions, please contact us.

As a professional black wire cloth manufacturer ,YESON will always suport your business 24/7

Black Wire Cloth Filter Screen Main Application Fields:

Mainly utilized for filtration within the plastics and rubber processing industry, as well as the chemical and pharmaceutical sectors, fifter screens find extensive application across various processes. They are commonly employed in PC, PP, PE, PS, HIPS, PET, PVC, and other plastic sheet extrusion, membrane machines, granulators, nonwoven fabric production, color masterbatch manufacturing, filler processing, and synthetic fiber extrusion, among others. Additionally, these screens play a crucial role in filtering gases and liquids, effectively separating foreign particles.

The fifter screen serves a variety of purposes, commonly found in applications such as PP and PS sheeting extrusion lines, foam extruders, pipe extruders, profile plastic extruders, plastic pipe extrusion lines, ram extruders, wire and cable production, profile extrusion, and plastic granulators. This versatile filter is also known by several names, including filter plastic pellets, filter discs, press out filter screens, extrusion machine filters, extruder filters, and rubber extruder filters.

How to use a Black Wire Cloth Filter Screen?

Here’s how to use a Black Wire Cloth Filter Screen:

Preparation: Ensure you have selected the appropriate size and specifications of the Black Wire Cloth Filter Screen to meet your filtration requirements. Clean the work area and ensure both the filter screen and related equipment are in a clean state.

Installation: Install the Black Wire Cloth Filter Screen correctly according to the requirements of your equipment. This may involve placing the filter screen at the inlet or outlet of the equipment or installing it in a specially designed filtration device.

Operation: Start the equipment and operate it according to the equipment’s operating manual. Ensure that the material passes smoothly through the Black Wire Cloth Filter Screen and that the filtration effect meets expectations.

Maintenance: Regularly inspect and clean the Black Wire Cloth Filter Screen to ensure it remains unobstructed. Replace the filter screen as needed to maintain filtration effectiveness.

Safety Precautions: Follow relevant safety procedures during use to ensure the safety of operators and equipment.

Regular Replacement as Needed: Regularly replace the filter screen based on usage and wear to ensure filtration effectiveness and proper equipment operation.

Overall, using a Black Wire Cloth Filter Screen requires careful operation based on specific circumstances and regular maintenance and replacement to ensure it effectively meets filtration needs.