Plastic pollution is indeed a critical issue, and plastic particle filter meshes provide a practical solution. These innovative devices effectively capture and remove plastic particles from different environments, helping to reduce plastic pollution. By preventing plastic waste from entering our oceans and waterways, we can safeguard marine ecosystems and human health.

Table of Contents

ToggleUnderstanding Plastic Particle Pollution

Plastic particles, commonly known as microplastics, are tiny fragments of plastic that can originate from a wide range of sources. These include the degradation of larger plastic items, synthetic fibers from clothing, and microbeads used in personal care products. Microplastics are ubiquitous, found in oceans, rivers, soil, and even the air we breathe.

The environmental impact of plastic particles is profound. Marine animals often mistake these particles for food, leading to ingestion that can cause physical harm, reproductive issues, and even death. Additionally, microplastics can absorb and transport toxic chemicals, further amplifying their harmful effects. For humans, the ingestion and inhalation of microplastics are a growing concern, although the full extent of the health risks is still under investigation.

What is a Plastic Particle Filter Mesh?

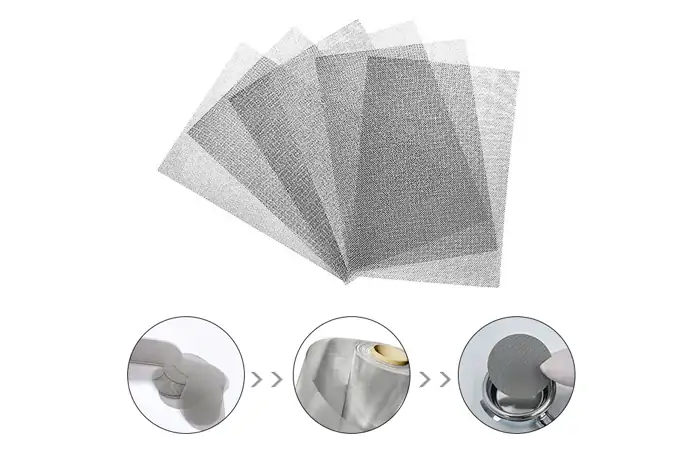

A plastic particle filter mesh is a specialized filtration device designed to trap and remove plastic particles from various media, such as water and air. These meshes are typically made from durable materials like stainless steel, nylon, or polyester, chosen for their effectiveness in capturing fine particles.

The working principle of these filters is straightforward. As water or air flows through the mesh, plastic particles are caught in the fine grid, while the filtered medium continues to pass through. The size of the mesh openings determines the size of the particles that can be captured, with finer meshes capable of trapping smaller particles.

Types of Plastic Particle Filter Mesh

Plastic particle filter meshes come in various materials, each with specific advantages and applications. Let’s explore the common materials used:

1.Stainless Steel Mesh:

Strength and Corrosion Resistance: Stainless steel meshes are renowned for their durability, strength, and resistance to corrosion. They can endure harsh conditions, making them ideal for industrial applications.

Applications: These meshes are commonly used in industrial processes, filtration systems, and environments where durability is essential.

2.Nylon Mesh:

Lightweight and Flexible: Nylon meshes are lightweight and flexible, making them suitable for various applications.

Household Use: They find use in household water and air purifiers, where their flexibility allows for easy installation and maintenance.

3.Polyester Mesh:

Durability and Affordability: Polyester meshes strike a balance between durability and cost-effectiveness.

Versatile Applications: They are employed in a wide range of contexts, from industrial processes (such as filtration and sieving) to personal care products (like cosmetic packaging).

Applications of Plastic Particle Filter Mesh

The versatility of plastic particle filter meshes makes them valuable in numerous settings:

1.Industrial Applications: Factories and manufacturing plants use these meshes to treat wastewater, ensuring that plastic particles do not enter the environment. They are also used in processes requiring clean water, such as food and beverage production.

2.Household Applications: Many water and air purifiers now incorporate plastic particle filter meshes to ensure that the water we drink and the air we breathe are free from microplastics. These devices are becoming increasingly popular as awareness of plastic pollution grows.

3.Environmental Cleanup Projects: Large-scale initiatives, such as ocean cleanup efforts, utilize filter meshes to collect plastic particles from water. These projects aim to reduce the overall burden of plastic pollution in marine environments.

Benefits of Using Plastic Particle Filter Mesh

The use of plastic particle filter meshes offers several significant benefits:

1.Efficiency: These meshes are highly effective at capturing even the smallest plastic particles, ensuring a cleaner environment.

2.Durability: Materials like stainless steel and polyester provide long-lasting filtration solutions, reducing the need for frequent replacements.

3.Cost-Effectiveness: Over time, the investment in durable filter meshes pays off by reducing the costs associated with environmental cleanup and health impacts.

4.Sustainability: By preventing plastic particles from entering natural ecosystems, these filters contribute to broader environmental conservation efforts.

How to Choose the Right Plastic Particle Filter Mesh

Selecting the appropriate filter mesh involves considering several factors:

1.Mesh Size: Determine the size of plastic particles that need to be filtered and choose a mesh with suitable openings.

2.Material: Consider the environment in which the filter will be used and select a material that offers the necessary durability and resistance to conditions.

3.Application: Match the filter to its intended use, whether for industrial processes, household purification, or environmental cleanup.

4.Installation and Maintenance: Ensure that the chosen filter can be easily installed and maintained to ensure long-term effectiveness.

Conclusion

Plastic particle filter meshes represent a vital tool in the fight against plastic pollution. By effectively capturing and removing plastic particles from water and air, these filters help protect ecosystems, marine life, and human health. As technology advances, the efficiency and applicability of these filters will only improve, offering hope for a cleaner, more sustainable future.

Appendices

Challenges and Limitations

Despite their advantages, plastic particle filter meshes do have some challenges:

1.Clogging: Fine meshes can become clogged with particles, requiring regular maintenance and cleaning.

2.Maintenance Requirements: Ensuring that the filters remain effective requires periodic checks and replacements.

3.Limitations in Certain Environments: In extremely polluted environments, filter meshes may need to be supplemented with other filtration methods to ensure comprehensive cleanup.

Innovations and Future Trends

The field of plastic particle filtration is rapidly evolving. Recent innovations include:

1.Advanced Materials: Development of new materials that offer better filtration efficiency and durability.

2.Integration with Other Systems: Combining filter meshes with other purification technologies, such as UV treatment and chemical filtration, to enhance overall effectiveness.

3.Smart Filters: Incorporating sensors and automation to monitor filter performance and optimize maintenance schedules.

Case Studies and Success Stories

Several successful implementations highlight the impact of plastic particle filter meshes:

1.Industrial Wastewater Treatment: A manufacturing plant in Germany reduced its plastic discharge by 90% after installing stainless steel filter meshes.

2.Household Water Purifiers: A leading brand of water purifiers reported a significant increase in sales following the introduction of plastic particle filters, reflecting growing consumer demand.

3.Ocean Cleanup Projects: The Great Pacific Garbage Patch project has successfully used filter meshes to collect thousands of tons of plastic particles, demonstrating the potential for large-scale environmental remediation.

FAQ: Plastic Particle Filter Mesh

1. Can plastic particle filter meshes be used in conjunction with other filtration methods?

Yes, they can be integrated with other purification technologies such as UV treatment and chemical filtration to enhance overall effectiveness.

2. How does a plastic particle filter mesh work?

The filter mesh works by allowing water or air to pass through its fine grid while trapping plastic particles. The size of the mesh openings determines the size of particles that can be captured.

3. What types of plastic particle filter meshes are available?

Common types include stainless steel mesh, nylon mesh, and polyester mesh, each suited for different applications and environments.

4. Where can plastic particle filter meshes be used?

They can be used in industrial wastewater treatment, household water and air purifiers, and environmental cleanup projects such as ocean and river filtration systems.

5. What are the benefits of using plastic particle filter meshes?

They are efficient in removing small plastic particles, durable, cost-effective over time, and contribute to environmental sustainability by preventing plastic pollution.

6. What are some challenges associated with plastic particle filter meshes?

Potential challenges include clogging, maintenance requirements, and limitations in heavily polluted environments where additional filtration methods may be needed.

7. How do I choose the right plastic particle filter mesh?

Consider factors such as mesh size, material, intended application, and ease of installation and maintenance.

8. Are there any innovations in plastic particle filter mesh technology?

Yes, recent innovations include advanced materials for better efficiency, integration with other purification systems, and smart filters with sensors and automation.

9. What maintenance is required for plastic particle filter meshes?

Regular cleaning to prevent clogging and periodic checks and replacements to ensure they remain effective are necessary.

10. How effective are plastic particle filter meshes in removing microplastics?

They are highly effective, particularly when the mesh size is appropriate for the size of the microplastics being targeted.