In industrial operations, clean oil is crucial for the efficient functioning of machinery and systems. Contaminants like dirt, metal particles, and debris can lead to excessive wear and tear, shorten equipment lifespan, and increase maintenance costs. Industrial oil filter screens are essential for addressing this issue. These screens are designed to filter out contaminants and ensure that only clean oil circulates through the equipment. In this blog, we’ll examine the role of industrial oil filter screens, how they work, their applications, and their importance across various industries.

Table of Contents

ToggleWhat is an Industrial Oil Filter Screen?

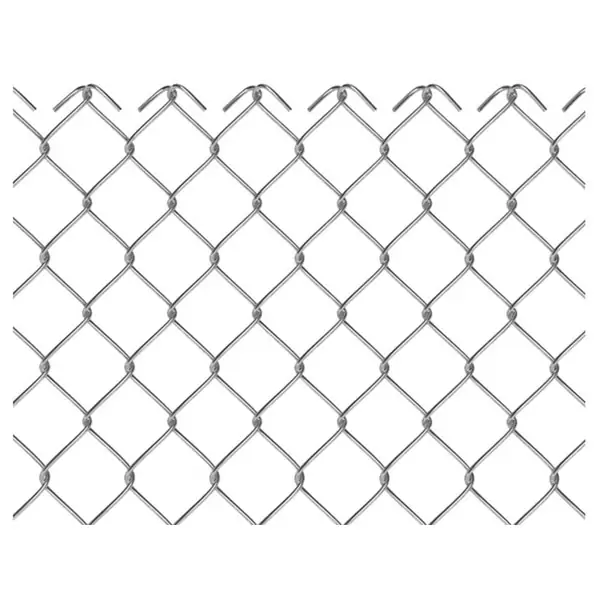

An industrial oil filter screen is a device designed to remove contaminants from oil used in machinery and other industrial processes. Its primary function is to filter out unwanted particles, ensuring that the oil circulating within the system remains clean and effective. These screens are typically made of metal mesh, synthetic fibers, or paper, depending on the specific application and the level of filtration required.

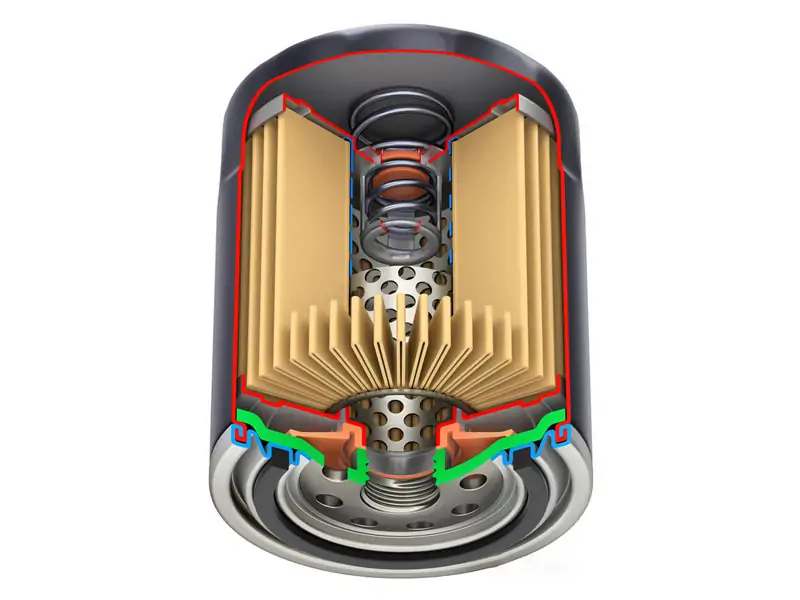

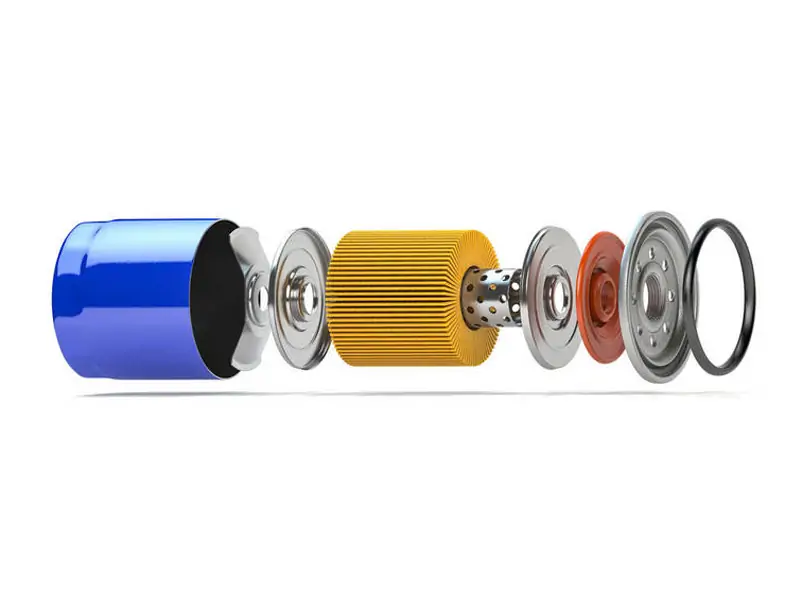

Components of an Oil Filter Screen:

- Mesh Screen:The core filtering element, which traps contaminants.

- Filter Housing:The structure that holds the filter in place within the system.

- Sealing Mechanism:Ensures that the oil flows through the filter screen without bypassing it.

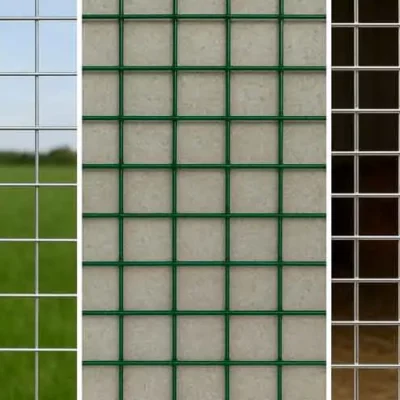

Types of Oil Filter Screens:

- Wire Mesh Filters:Durable and reusable, commonly used in heavy-duty applications.

- Synthetic Fiber Filters:Known for their high filtration efficiency and are often used in precision machinery.

- Paper Filters:Cost-effective and disposable, suitable for less demanding applications.

How Industrial Oil Filter Screens Work

The process by which industrial oil filter screens operate is straightforward yet highly effective. As oil passes through the system, it flows through the filter screen, where contaminants are captured. The filtered oil then continues its journey through the machinery, free of harmful particles.

Key Factors Influencing Filtration Efficiency:

- Mesh Size:The finer the mesh, the smaller the particles it can capture.

- Flow Rate:Higher flow rates may require larger or multiple filters to maintain efficiency.

- Oil Viscosity:Thicker oils may require specific filter designs to ensure effective filtration.

Applications of Industrial Oil Filter Screens

Industrial oil filters have their own unique requirements and challenges in every industry. Here are some of the key areas where these filters play an important role:

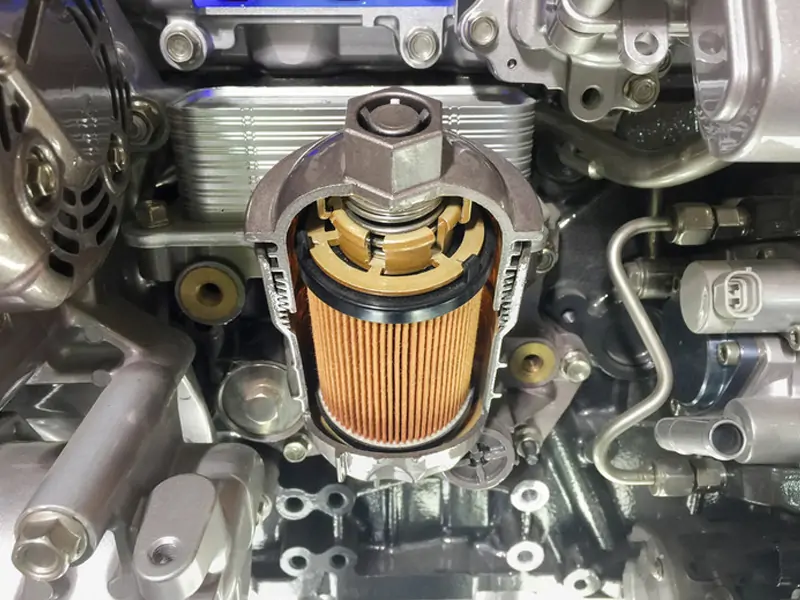

- Automotive Manufacturing:Ensuring that lubricants and hydraulic fluids remain clean to prevent engine and component wear.

- Power Generation:Protecting turbines and generators by filtering out contaminants from the lubricating oil.

- Heavy Machinery and Equipment:Maintaining the efficiency and longevity of large-scale industrial equipment, such as excavators and cranes.

In these industries, oil filter screens are essential for protecting expensive machinery and minimizing downtime due to maintenance or repairs. For example, in automotive manufacturing, a clogged filter could lead to engine failure, while in power generation, it could cause costly outages.

The Importance of Regular Maintenance and Replacement

Like any other component, industrial oil filter screens require regular maintenance to function effectively. Over time, the filter can become clogged with trapped particles, reducing its efficiency and potentially causing damage to the machinery it is meant to protect.

Signs of a Clogged or Worn-Out Filter:

- Reduced Oil Flow:Indicating that the filter is restricting the flow of oil due to clogging.

- Increased Operating Temperatures:A sign that the machinery is working harder due to poor lubrication.

- Visible Wear and Tear:On the filter housing or the mesh itself.

Impact of Neglecting Filter Maintenance:

Neglecting to maintain or replace oil filter screens can decrease efficiency, elevate energy usage, and potentially lead to severe equipment malfunctions. Over time, these issues may result in considerable financial losses due to repair expenses and operational downtime.

Best Practices for Maintenance and Replacement:

- Regular Inspections:Check filters at scheduled intervals to ensure they are not clogged or damaged.

- Timely Replacements:Replace filters according to the manufacturer’s recommendations or when signs of wear are evident.

- Use High-Quality Filters:Invest in filters that are suited to the specific demands of your machinery to ensure optimal performance.

Advancements in Oil Filter Screen Technology

As industries evolve, so too does the technology behind oil filtration. Recent advancements have led to the development of more efficient and environmentally friendly filter screens.

Recent Innovations Include:

- Improved Filtration Materials:New materials that offer better filtration efficiency and longer life spans.

- Smart Filtration Systems:Sensors and monitoring systems that provide real-time data on filter performance and oil quality.

- Environmentally Friendly Designs:Filters that are easier to recycle or dispose of, reducing their environmental impact.

These advancements not only improve the performance and reliability of industrial machinery but also contribute to more sustainable practices in various industries.

Conclusion and recommendations

While industrial oil filter screens might appear to be a minor component within large machinery, their role is vital. They are essential for preserving the efficiency, reliability, and lifespan of equipment in various industries. By keeping oil free from contaminants, these filters help avoid expensive failures and extend machinery life. As technology evolves, the importance of oil filter screens will likely grow, fostering further innovation and supporting sustainable industrial practices.

Whether you work in automotive manufacturing, power generation, or heavy machinery, recognizing the importance of industrial oil filter screens and maintaining them properly is crucial for ensuring smooth and efficient operations.