Table of Contents

ToggleIntroduction

In the realm of water treatment, filtration plays a pivotal role in ensuring clean, safe, and potable water for communities and industries. As such, the materials used in filtration systems need to be highly durable, efficient, and resistant to the many challenges posed by water treatment processes. This is where epoxy coated wire mesh stands out as a superior choice for water treatment plant filters.

Epoxy coated wire mesh is a highly durable and corrosion-resistant material that provides long-term reliability in water filtration systems. This pillar post will explore why epoxy coated wire mesh is the ideal solution for water treatment plants, diving into its features, benefits, applications, and the factors to consider when selecting it for your filtration needs.

Understanding Water Treatment Filtration Systems

What Are Water Treatment Plants?

Water treatment plants are complex facilities designed to clean and purify water by removing contaminants such as bacteria, viruses, dirt, chemicals, and other harmful substances. These plants serve a critical function in providing clean water for municipal use, industrial processes, agriculture, and other applications.

Water treatment generally occurs in three main stages:

- Primary Treatment: The removal of large particles through physical processes such as screening.

- Secondary Treatment: Biological processes, where bacteria and other microorganisms break down organic matter.

- Tertiary Treatment: Advanced methods such as filtration, chemical treatment, or membrane processes to remove remaining contaminants.

Role of Filtration in Water Treatment

Filtration is a crucial stage in the treatment process. It removes particulate matter, sediments, and even microorganisms that might still be present after initial treatments. Different types of filters, including sand filters, cartridge filters, and membrane filters, are employed to purify water effectively. The efficiency of these filtration systems depends heavily on the quality of the filter material.

Challenges in Filtration Systems

Despite their importance, filtration systems often face challenges. Clogging, corrosion, and degradation of filter materials are common issues. Water treatment environments are harsh, with high flow rates, chemical exposure, and constant wear-and-tear. This makes selecting the right material for filtration essential to maintaining optimal performance and reducing operational costs.

What is Epoxy Coated Wire Mesh?

Definition of Epoxy Coated Wire Mesh

Epoxy coated wire mesh consists of a metal wire, typically steel, coated with a layer of epoxy resin. This coating enhances the material’s resistance to corrosion, rust, and chemical damage, making it ideal for environments like water treatment plants where exposure to water, chemicals, and high humidity is common.

Properties That Make It Suitable for Filtration

Epoxy coated wire mesh has several key properties that make it a standout material for water filtration:

- Corrosion Resistance: The epoxy coating protects the wire mesh from rust and corrosion, which is particularly important in water treatment environments where the mesh is in constant contact with water and various chemicals.

- Strength and Durability: The mesh is strong enough to withstand the mechanical stresses of filtration, while the epoxy coating helps maintain its integrity over time.

- Smooth Surface: The coating creates a smooth surface that minimizes friction and prevents clogging, improving the overall filtration efficiency.

- Flexibility: Epoxy coated wire mesh is customizable, with various mesh sizes and gauges available to meet specific filtration needs.

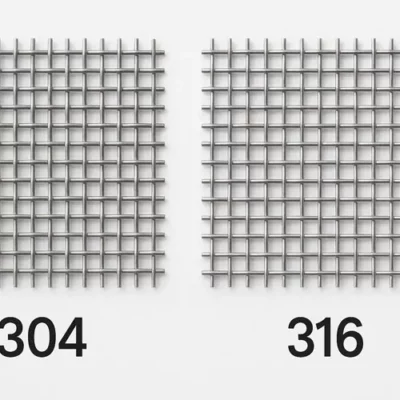

Comparison to Other Materials

When compared to untreated wire mesh or materials like stainless steel, epoxy coated wire mesh offers superior corrosion resistance and longevity. While stainless steel is highly durable, it can still be prone to corrosion in certain environments. Epoxy coating provides an added layer of protection, extending the lifespan of the mesh and reducing the need for frequent replacements.

Benefits of Epoxy Coated Wire Mesh for Water Treatment Filters

Enhanced Durability and Longevity

The primary advantage of epoxy coated wire mesh is its enhanced durability. The epoxy coating acts as a protective barrier against rust, corrosion, and physical wear, even in harsh conditions. This is especially important in water treatment plants, where filtration systems are subject to high moisture levels and chemical exposure. The mesh can last for years without needing frequent maintenance or replacement, ensuring continuous operation and reducing long-term costs.

Improved Filtration Performance

Epoxy coated wire mesh also contributes to improved filtration efficiency. The smooth surface of the mesh prevents debris from getting stuck in the gaps, reducing clogging. This ensures that water flows freely through the filter, maintaining high filtration performance over time. Furthermore, the wire mesh structure allows for precise control over the filtration process, making it ideal for fine filtration applications.

Cost-Effectiveness

Though the initial cost of epoxy coated wire mesh may be slightly higher than untreated wire mesh, its durability and performance quickly lead to cost savings. The longevity of the material reduces the need for frequent replacements, and its resistance to clogging and corrosion decreases maintenance costs. Over time, this results in a more cost-effective filtration solution, especially in high-volume water treatment facilities.

Resistance to Harsh Chemicals

Water treatment plants often deal with harsh chemicals like chlorine, acids, and alkalis that can degrade materials over time. Epoxy coated wire mesh is highly resistant to these chemicals, making it ideal for chemical dosing systems and other water treatment processes where exposure to aggressive substances is a concern.

Applications of Epoxy Coated Wire Mesh in Water Treatment Plants

Types of Filters Used in Water Treatment Plants

Water treatment plants utilize a variety of filtration systems, each designed for specific tasks:

- Mechanical Filters: These filters remove large particles and debris from the water, usually as the first step in the treatment process. Examples include sand filters and cartridge filters.

- Pressure Filters and Gravity Filters: These are used in situations where high pressure is needed to push water through a filter bed.

- Membrane Filters (Reverse Osmosis): These filters are used for advanced filtration, especially for desalination and purifying water at the molecular level.

Specific Use Cases for Epoxy Coated Wire Mesh

Epoxy coated wire mesh is used in various filtration applications within water treatment plants, including:

- Filter Screens and Baskets: These mesh filters capture large particles and debris, ensuring that only clean water passes through the system.

- Pre-Filters: Epoxy coated wire mesh is used as a pre-filter to protect more delicate filtration systems from debris and larger particles.

- Strainers in Chemical Dosing Systems: In chemical treatment, the mesh helps remove particulate matter before chemicals are introduced to the water.

Case Studies of Water Treatment Plants Using Epoxy Coated Wire Mesh

Several water treatment plants around the world have adopted epoxy coated wire mesh for their filtration systems. For instance, a municipal water treatment facility in California reported a significant reduction in maintenance costs after switching to epoxy coated mesh, as the material’s corrosion resistance ensured fewer replacements and repairs. Similarly, an industrial water treatment plant in Germany found that the mesh improved filtration efficiency and reduced energy consumption due to the smooth surface preventing clogging.

How to Choose the Right Epoxy Coated Wire Mesh for Water Treatment Filters

Factors to Consider

When selecting epoxy coated wire mesh for water treatment plants, several factors need to be considered:

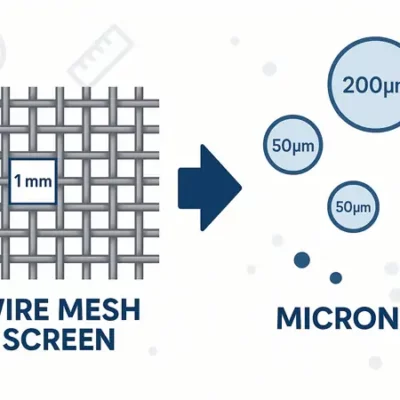

- Mesh Size and Gauge: The mesh size determines how fine the filtration will be, and the gauge indicates the thickness of the wire. Choose the appropriate combination based on the type of particles you need to filter.

- Coating Thickness: The thickness of the epoxy coating impacts the level of protection against corrosion. Thicker coatings offer better protection, especially in highly corrosive environments.

- Resistance Requirements: Consider the chemicals, temperature, and flow rate involved in your water treatment process. The mesh should be able to withstand these factors without deteriorating.

Selecting the Best Supplier for Epoxy Coated Wire Mesh

Not all epoxy coated wire mesh is created equal. When selecting a supplier, look for:

- Quality Standards: Ensure the supplier adheres to industry standards for quality and durability.

- Customization Options: Choose a supplier that can customize the mesh size, gauge, and coating thickness to meet your specific filtration needs.

- Customer Service: A good supplier will offer excellent customer service, including technical support and guidance in selecting the right mesh.

Common Mistakes to Avoid

- Oversizing or Undersizing the Mesh: Ensure that the mesh size and gauge are suitable for your filtration requirements.

- Choosing Low-Quality Coatings: Always opt for a high-quality epoxy coating to ensure durability and performance.

Maintenance and Care for Epoxy Coated Wire Mesh in Water Treatment Plants

Routine Maintenance Tips

To maximize the lifespan of epoxy coated wire mesh, perform regular maintenance:

- Cleaning: Rinse the mesh with water to remove debris and buildup. For heavy contamination, use a mild cleaning solution.

- Inspecting for Damage: Regularly inspect the mesh for signs of damage, such as cracks or worn areas in the epoxy coating.

Signs of Wear and Tear

Over time, even the most durable materials can show signs of wear. Look for:

- Cracking or Peeling Coating: This is a sign that the epoxy coating is no longer providing adequate protection.

- Clogging: If the mesh becomes clogged more frequently, it could indicate a degradation of the material.

Longevity and Replacement Scheduling

Epoxy coated wire mesh can last for several years with proper care. However, it’s essential to monitor the condition of the mesh and replace it when necessary to maintain filtration efficiency.

Future Trends in Water Treatment Filtration and Epoxy Coated Wire Mesh

Innovations in Filtration Technology

As water treatment technology evolves, so too does the demand for more efficient, sustainable materials. Innovations in epoxy coatings, mesh designs, and filtration technologies are expected to further enhance the performance of water treatment systems.

The Role of Epoxy Coated Wire Mesh in the Future of Water Treatment

Epoxy coated wire mesh will continue to play a critical role in water treatment filtration due to its durability, cost-effectiveness, and resistance to harsh conditions. As the demand for cleaner water and more efficient systems grows, this material will remain an essential component in modern water treatment plants.

FAQs

What is the lifespan of epoxy coated wire mesh in water filtration?

Epoxy coated wire mesh can last several years, depending on the conditions of the water treatment plant. Regular maintenance and care can significantly extend its lifespan.

Can epoxy coated wire mesh be used in other filtration systems beyond water treatment?

Yes, epoxy coated wire mesh can be used in a variety of filtration systems, including those used for air, oil, and food processing.

How does epoxy coated wire mesh compare to plastic mesh in filtration?

Epoxy coated wire mesh offers superior durability, corrosion resistance, and strength compared to plastic mesh, making it ideal for harsher filtration environments.

Is epoxy coated wire mesh more expensive than other types of mesh?

The initial cost of epoxy coated wire mesh may be higher than untreated or plastic mesh, but its durability and performance lead to long-term cost savings.

Conclusion

Epoxy coated wire mesh offers an ideal solution for water treatment plant filters, combining durability, corrosion resistance, and efficiency. By selecting the right mesh for your filtration system, you can reduce maintenance costs, improve filtration performance, and ensure the long-term sustainability of your water treatment operations. With its many benefits, epoxy coated wire mesh is undoubtedly the perfect fit for water treatment plants looking to optimize their filtration systems.