Today, we’re bringing you a fascinating look at a variety of production processes. We will explore the production process of anti-climb spikes in our factory. These anti-climb spikes play a vital role in ensuring security and protecting property from trespassing. Below, follow us as we learn more about these superb processes.

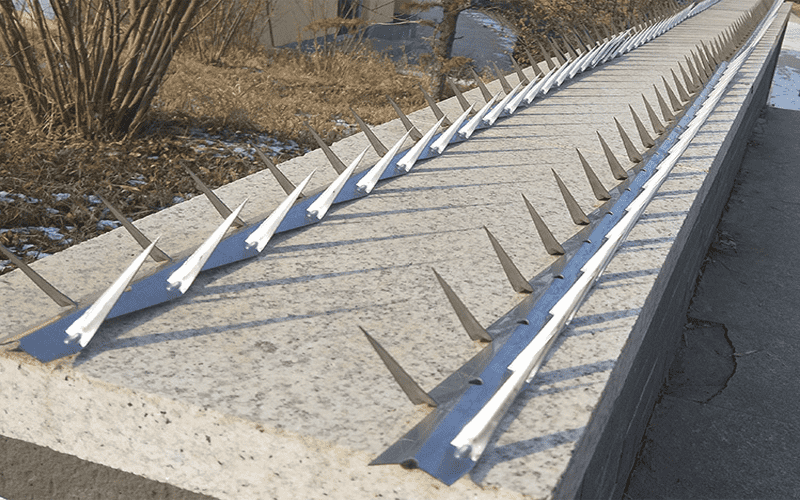

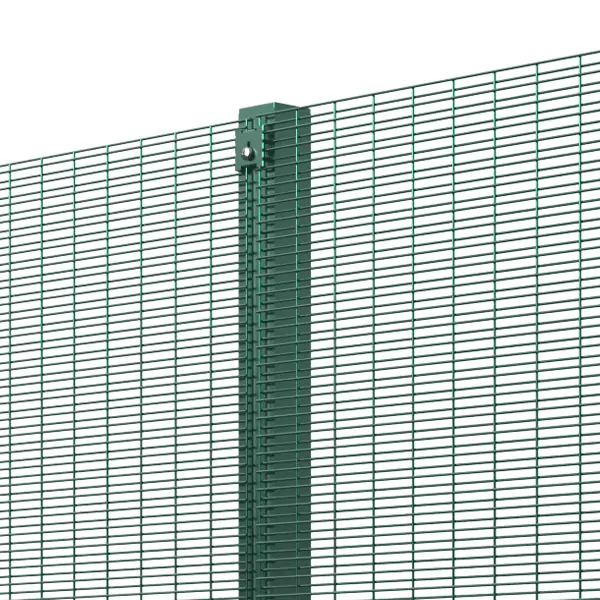

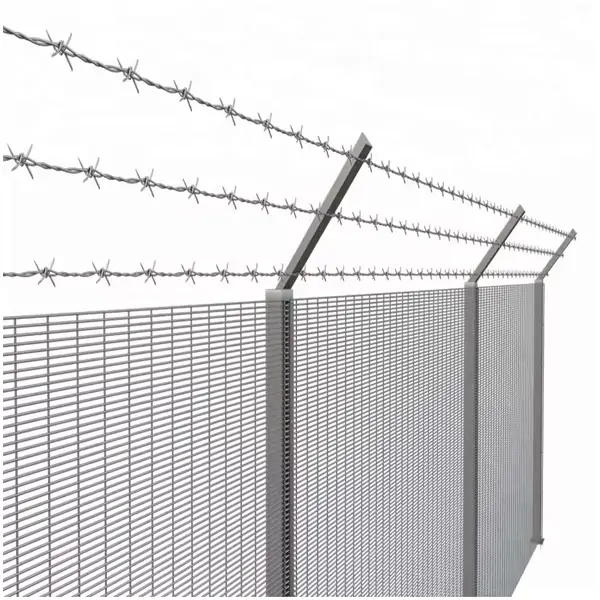

To kick-start our journey, let’s understand the significance of anti-climb spikes in keeping our premises safe. These sharp, pyramidal structures act as a powerful deterrent against any potential climbing attempts. By effectively preventing unauthorized individuals from scaling perimeter walls and fences, anti-climb spikes provide an added layer of security, especially in sensitive areas like warehouses, military compounds, or high-security facilities. Now, let’s dive straight into the production steps that transform raw materials into the robust anti-climb spikes we’re familiar with.

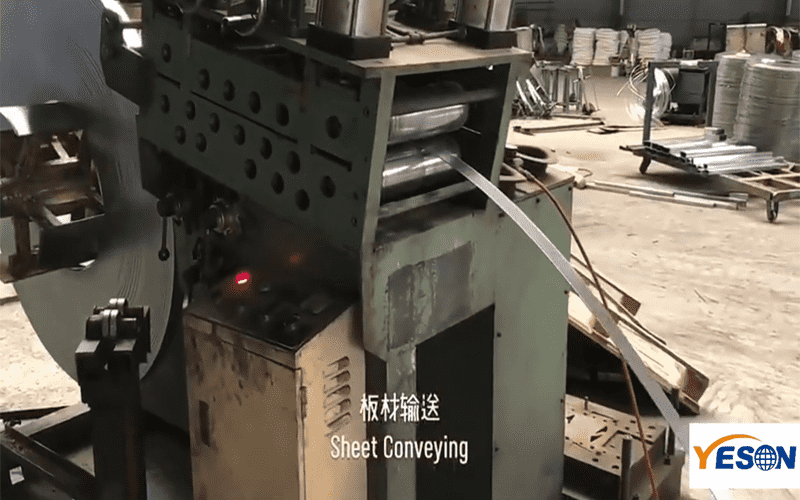

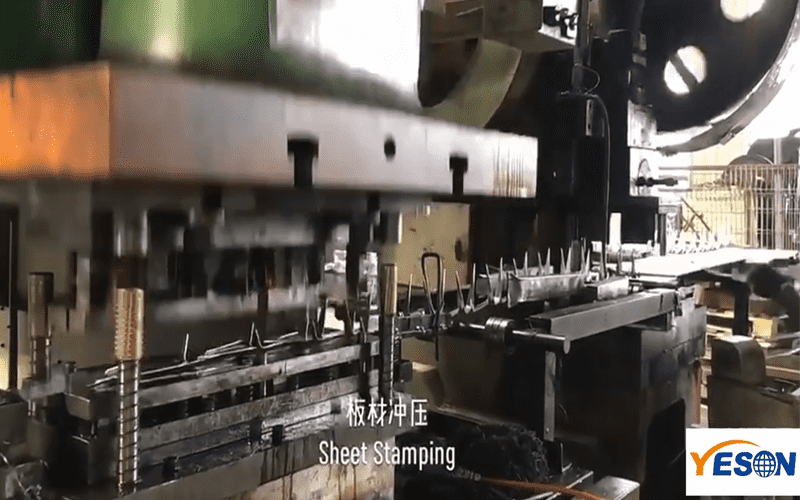

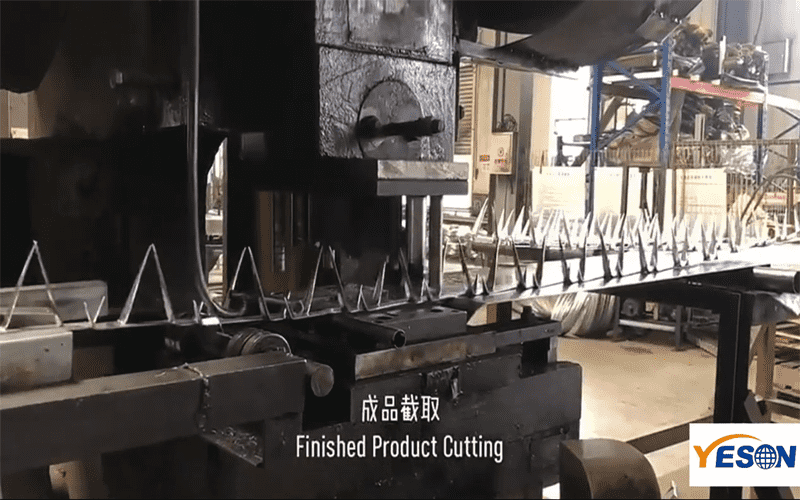

The production process begins with careful selection of high-quality materials, typically steel, known for its durability. The first step involves cutting the steel rods into appropriate lengths, ensuring optimal functionality for the spikes. Once the rods are cut, they proceed to the shaping process. Here, advanced machinery is used to form the pyramidal shape of the spikes, carefully grinding and molding them with precision. The spikes are held firmly in place during this process to ensure a consistent and uniform outcome.

Next, the spikes undergo a galvanization process that enhances their resistance to corrosion. This involves dipping them into a specialized zinc bath, ensuring a coating that prevents rust and extends their lifespan. The spikes are then carefully inspected for quality control, eliminating any irregularities or imperfections that may compromise their effectiveness.

As the final step in the production process, the spikes are prepped for packaging and distribution. They are sorted, counted, and organized according to the specific requirements of customers. This ensures easy installation and allows customers to secure their premises effectively. The packaging stage prioritizes safety, employing sturdy materials that prevent any accidental injuries during storage or transit.

Ultimately, every stage of producing anti-climbing nails is rigorously carried out to ensure the highest standards in terms of quality, durability and reliability. With state-of-the-art machinery, experienced engineers and rigorous quality checks, it is only through these anti-climbing spikes that they are able to effectively protect a multitude of facilities and enhance the security of homeowners.

At this point, we know the factory production process behind anti-climbing spikes. From understanding the importance of anti-climbing spikes in preventing break-ins to witnessing the meticulous production steps, we hope this blog has enlightened you. If you’d like to learn more about the excitement of anti-climb spikes. Please contact us!