Welcome to our comprehensive guide on the versatile applications of Black Wire Cloth Filter Mesh! In this detailed exploration, we’ll delve into the various uses, benefits, and installation techniques of this essential filtration material. Whether you’re a seasoned professional or a curious newcomer, join us as we uncover the remarkable capabilities of Black Wire Cloth Filter Mesh.

PS: If you are looking for a Black Wire Cloth company, Anping Yeson Wire Mesh Products Co., Ltd. must be a good choice. Anping Yeson Wire Mesh Products Co., Ltd. has established itself as a top manufacturer of Black Wire Cloth within just 30 years- and a premier manufacturer of wire mesh and fences in China.

Table of Contents

ToggleIntroduction to Black Wire Cloth Filter Mesh:

What is Black Wire Cloth Filter Mesh?

Black wire cloth filter mesh is a type of wire mesh typically made from low carbon steel wire or iron wire. It is woven into a plain weave or twill weave pattern, forming a fine mesh with uniform openings. The term “black” in black wire cloth refers to the color of the wire after it has been annealed or coated, giving it a black appearance.

This type of wire cloth is commonly used for filtration purposes due to its durability, corrosion resistance, and ability to withstand high temperatures. It is often utilized in various industries such as mining, chemical processing, food and beverage, pharmaceuticals, and water treatment.

Black wire cloth filter mesh is a versatile filtration solution renowned for its ability to effectively capture solid particles and impurities from liquids and gases. Its adaptability makes it ideal for applications demanding precise filtration. Whether employed as filter discs, cylinders, belts, or elements within diverse filtration systems, this mesh offers reliable performance. Mesh size and wire diameter are customizable to meet the specific filtration needs of various industries, including mining, chemical processing, food and beverage, pharmaceuticals, and water treatment. With its durability, corrosion resistance, and capacity to withstand high temperatures, black wire cloth filter mesh stands as a trusted choice for critical filtration tasks.

How does it differ from other filtration materials?

Black wire cloth filter mesh differs from other filtration materials in several key aspects:

1. Material Composition: Black wire cloth filter mesh is typically made from low carbon steel wire or iron wire, while other filtration materials may be composed of materials such as stainless steel, nylon, polyester, or other synthetic materials.

2. Construction: The construction of black wire cloth involves weaving the wire into a plain weave or twill weave pattern, creating a fine mesh with uniform openings. Other filtration materials may be constructed using different techniques such as sintering, extrusion, or knitting.

3. Filtration Efficiency: The filtration efficiency of black wire cloth filter mesh depends on factors such as mesh size, wire diameter, and weave pattern. It can effectively filter solid particles and impurities from liquids and gases, but the filtration efficiency may vary compared to other materials depending on their specific characteristics.

4. Durability and Temperature Resistance: Black wire cloth filter mesh is renowned for its exceptional durability, corrosion resistance, and capability to endure high temperatures, rendering it ideal for rigorous industrial applications. In contrast, alternative filtration materials may exhibit varying degrees of durability and temperature resistance contingent upon their composition and manufacturing processes.

5. Application Versatility: Black wire cloth filter mesh finds widespread use across diverse industries and applications, ranging from mining and chemical processing to food and beverage, pharmaceuticals, and water treatment. In contrast, alternative filtration materials may be tailored for specific applications or industries, offering a narrower scope of utility.

Ultimately, the selection of filtration material hinges on various factors including specific filtration criteria, operational environments, and budgetary considerations. Each material presents unique advantages and limitations, underscoring the importance of choosing the most appropriate option based on desired filtration efficacy and application prerequisites.

Key features and specifications.

Key Features and Specifications of Black Wire Cloth Filter Mesh:

1. Material: Typically manufactured from low carbon steel wire or iron wire.

2. Weave Pattern: Available in plain weave or twill weave patterns.

3. Mesh Size: Customizable to suit specific filtration requirements, ranging from fine to coarse.

4. Wire Diameter: Varied wire diameters to accommodate different filtration tasks.

5. Color: After annealing or coating, the wire acquires a black appearance.

6. Durability: Renowned for its robustness and longevity, suitable for demanding industrial applications.

7. Corrosion Resistance: Exhibits resistance to corrosion, enhancing longevity in corrosive environments.

8. Temperature Resistance: Capable of withstanding high temperatures, ensuring reliable performance in elevated temperature conditions.

9. Filtration Efficiency: Effectively captures solid particles and impurities from liquids and gases, with filtration efficiency depending on mesh size, wire diameter, and weave pattern.

10. Versatility: Widely used across industries including mining, chemical processing, food and beverage, pharmaceuticals, and water treatment.

11. Customization: Available in various sizes, configurations, and specifications to meet specific filtration needs.

12. Application: Suitable for filter discs, cylinders, belts, and elements in different filtration systems.

These key features and specifications make black wire cloth filter mesh a versatile and reliable choice for diverse filtration applications.

Applications Across Industries:

Filtration in industrial settings.

Environmental applications.

Agricultural uses.

Construction and infrastructure projects.

Installation Techniques:

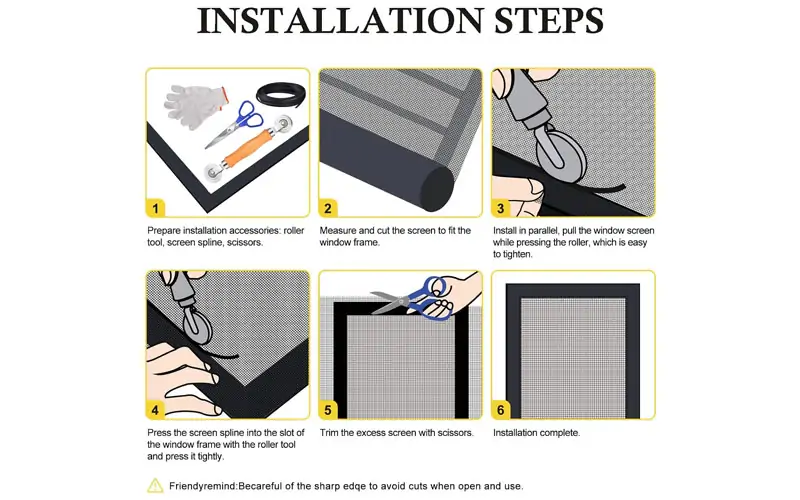

Proper installation methods.

Ensuring proper installation of black wire cloth filter mesh is essential to guarantee effective filtration and optimal performance. Here are some general guidelines for installation:

1. Surface Preparation: Prior to installation, it is imperative to clean the surface thoroughly to remove any debris or contaminants that could potentially compromise filtration performance. Ensure the surface is flat and free from any obstructions that may hinder proper placement of the wire cloth.

2. Cutting to Size: Cut the wire cloth to the required dimensions using appropriate tools such as wire cutters or shears. Ensure that the edges are smooth to prevent snagging or damage during installation.

3. Securing the Mesh: Depending on the application, the wire cloth may need to be fastened securely using appropriate methods such as bolts, screws, or clips. It’s essential to ensure that the mesh is firmly secured to prevent any potential shifting or movement during operation, which could compromise filtration efficiency.

4. Proper Alignment: Align the wire cloth properly with the filtration system or equipment to ensure that it covers the entire filtration area evenly. This will help prevent bypassing of contaminants and ensure uniform filtration.

5. Tensioning: If necessary, tension the wire cloth to remove any wrinkles or slackness that could affect filtration performance. Be careful not to over-tension the mesh, as this could cause deformation or damage.

6. Sealing: In some applications, it may be necessary to seal the edges of the wire cloth to prevent leakage or bypassing of contaminants. Use appropriate sealing materials such as gaskets, adhesives, or sealant tapes.

7. Regular Inspection: After installation, regularly inspect the wire cloth for signs of damage, wear, or clogging. Replace or clean the mesh as needed to maintain optimal filtration performance.

8. Follow Manufacturer Recommendations: Follow any specific installation instructions or recommendations provided by the manufacturer to ensure proper installation and optimal performance of the wire cloth filter mesh.

By following these proper installation methods, you can ensure that black wire cloth filter mesh performs effectively and reliably in your filtration system.

Maintenance tips for optimal performance.

To maintain optimal performance of black wire cloth filter mesh, consider the following maintenance tips:

1. Regular Cleaning: Periodically clean the wire cloth to remove accumulated debris, particles, and contaminants. Use appropriate cleaning methods such as brushing, rinsing with water, or gentle agitation to avoid damaging the mesh.

2. Inspection: Conduct regular visual inspections of the wire cloth to check for signs of wear, damage, or clogging. Look for tears, holes, or irregularities in the mesh that could affect filtration efficiency.

3. Replacement: Replace the wire cloth as needed, especially if it becomes worn out, damaged, or clogged beyond cleaning. Follow manufacturer recommendations for replacement intervals based on usage and operating conditions.

4. Proper Handling: Handle the wire cloth with care to prevent damage during installation, cleaning, or maintenance activities. Avoid sharp objects or rough handling that could tear or puncture the mesh.

5. Avoiding Harsh Chemicals: Opt for mild cleaning agents over harsh chemicals or abrasive cleaners to prevent corrosion or damage to the wire cloth. Refer to manufacturer guidelines for recommended cleaning solutions that are compatible with the material composition of the wire cloth.

6. Maintain Proper Tension: Ensure that the wire cloth is properly tensioned to prevent sagging or slackness, which could affect filtration performance. Adjust tension as needed to maintain uniform mesh alignment.

7. Monitor Filtration Efficiency: Regularly monitor filtration performance to ensure that the wire cloth is effectively capturing particles and contaminants. Adjust filtration parameters or cleaning frequency as needed to maintain optimal efficiency.

Compatibility with different systems and equipment.

Black wire cloth filter mesh exhibits compatibility with a wide array of filtration systems and equipment across various industries. Its versatility makes it suitable for integration into different types of filtration setups, including:

1. Filtration Vessels: Black wire cloth filter mesh can be incorporated into standard filtration vessels or housings, allowing for effective removal of solid particles and impurities from liquids or gases.

2. Filter Discs and Screens: The mesh can be fashioned into filter discs or screens that are compatible with various filtration assemblies, such as cartridge filters or strainers, ensuring efficient particle removal.

3. Filter Elements: Custom-made filter elements utilizing black wire cloth mesh can be designed to fit specific filtration equipment, providing tailored filtration solutions for different applications.

4. Filter Presses: Black wire cloth filter mesh can be utilized in filter press applications for solid-liquid separation processes, offering reliable filtration performance under high-pressure conditions.

5. Centrifuges: It can be employed in centrifuge systems for solid-liquid separation, facilitating the removal of fine particles from liquids.

6. Fluid Bed Dryers: Black wire cloth filter mesh can be utilized as screens in fluid bed dryers to ensure uniform drying and particle size distribution.

7. Sifters and Sieves: It is suitable for use in vibratory sifters and sieves for particle size classification and separation in various industries.

8. Strainers and Screens: Black wire cloth mesh can be installed as strainers or screens in piping systems to prevent debris from entering sensitive equipment or processes.

As we conclude our journey through the world of Black Wire Cloth Filter Mesh, we hope you’ve gained valuable insights into its versatile applications and benefits. Whether you’re seeking reliable filtration solutions for industrial, environmental, or agricultural purposes, Black Wire Cloth Filter Mesh offers unparalleled performance and reliability. Thank you for joining us on this exploration, and we look forward to continuing to serve your filtration needs in the future.