Table of Contents

ToggleWhat is a steel grate?

A steel grate is a versatile and durable structure composed of interlaced steel bars or panels. It serves various functions across different industries and environments. Essentially, it acts as a rigid, supportive platform with gaps or openings that allow for the passage of air, water, or light while still providing structural integrity.

Think of steel grates as the unsung heroes of infrastructure. You’ve probably walked over them countless times without even realizing it. From sidewalks and bridges to drainage systems and industrial machinery, steel grates play a crucial role in our daily lives.

Imagine strolling through a bustling city, the rhythmic clack of your footsteps echoing as you traverse the sidewalk. Beneath your feet lies a network of steel grates, diligently channeling rainwater away from the streets, preventing flooding, and maintaining the city’s infrastructure.

But steel grates aren’t just confined to urban landscapes. They find their place in industrial settings too, where their robust construction and corrosion-resistant properties make them invaluable. Whether it’s in factories, warehouses, or even agricultural facilities, steel grates offer unmatched strength and reliability.

In essence, a steel grate is more than just a simple metal structure. It’s a silent guardian, ensuring the safety, functionality, and efficiency of the spaces we inhabit. So, the next time you encounter one, take a moment to appreciate the unsung hero beneath your feet—the humble yet indispensable steel grate.

PS: If you are looking for a Steel Grate company, Anping Yeson Wire Mesh Products Co., Ltd. must be a good choice. Anping Yeson Wire Mesh Products Co., Ltd. has established itself as a top manufacturer of Steel Grate within just 30 years- and a premier manufacturer of wire mesh and fences in China.

Why use steel grate?

Steel grates are favored for a multitude of reasons across various industries and applications. Here’s why they’re the go-to choice:

1. Durability: Steel grates are renowned for their exceptional durability. Made from high-quality steel, they can withstand heavy loads, harsh weather conditions, and constant use without deteriorating. This durability ensures a long lifespan, reducing the need for frequent replacements and saving both time and money in the long run.

2. Strength: One of the key reasons for using steel grates is their remarkable strength. The interlaced steel bars or panels are engineered to provide robust support, making them ideal for applications where structural integrity is paramount. Whether it’s supporting pedestrian traffic on sidewalks or heavy machinery in industrial settings, steel grates can handle the load with ease.

3. Versatility: Steel grates come in a variety of designs and configurations to suit different purposes. Whether you need them for drainage systems, pedestrian walkways, or industrial flooring, there’s a steel grate to meet your specific requirements. This versatility makes them a versatile solution for a wide range of applications.

4. Corrosion Resistance: Steel grates are inherently resistant to corrosion, thanks to the protective properties of steel. This makes them particularly well-suited for outdoor use, where exposure to moisture, chemicals, and other corrosive elements is common. By choosing steel grates, you can ensure that your infrastructure remains intact and functional for years to come.

5. Safety: Steel grates offer excellent traction, reducing the risk of slips and falls, especially in wet or slippery conditions. The open design allows water, snow, and debris to pass through, minimizing the chances of puddles or accumulation that could pose a safety hazard. Additionally, the sturdy construction of steel grates provides a stable surface for pedestrians and vehicles alike, enhancing overall safety.

In summary, the use of steel grates is driven by their durability, strength, versatility, corrosion resistance, and safety benefits. Whether it’s for drainage systems, industrial flooring, or pedestrian walkways, steel grates offer a reliable solution that stands the test of time.

What are the different types of steel grates?

Steel grates come in various types, each tailored to specific applications and environments. Here’s a breakdown of the different types you might encounter:

1. Bar Grating: Bar grating is perhaps the most common type of steel grate, featuring interlaced steel bars arranged in perpendicular patterns. This design provides excellent strength and support while allowing for the passage of air, light, and fluids. Bar grating is commonly used in industrial flooring, platforms, and catwalks due to its durability and load-bearing capacity.

2. Welded Steel Grating: Welded steel grating comprises welded steel panels interconnected with flat bars and crossbars at their junctions. Renowned for its exceptional strength and stability, this type of grating is ideal for demanding applications including vehicular traffic, loading docks, and trench covers. Its sturdy construction and resistance to deformation make welded steel grating a reliable choice for various heavy-duty tasks.

3. Press-Locked Grating: Press-locked grating features interlocking bars that are mechanically locked together under high pressure. This results in a tight grid pattern that enhances load distribution and prevents the bars from shifting or rattling. Press-locked grating is commonly used in architectural applications, such as building facades, sunshades, and decorative screens, where aesthetics and durability are key.

4. Riveted Grating: Riveted grating consists of steel bars and crossbars that are joined together with rivets, creating a rigid and stable structure. This type of grating is characterized by its classic appearance and high strength-to-weight ratio, making it suitable for bridges, mezzanines, and walkways. Riveted grating offers exceptional durability and resistance to impact and fatigue.

5. Expanded Metal Grating: Expanded metal grating is crafted by cutting and expanding a sheet of metal to form a pattern of diamond-shaped apertures. Known for its lightweight nature and robustness, this grating provides excellent traction and ventilation. Widely employed in catwalks, fencing, and security screens, it ensures both visibility and airflow, making it a preferred choice for various applications.

These examples merely scratch the surface of the extensive variety of steel grates on the market. Whether your demands lean towards heavy-duty industrial applications or more aesthetic considerations for architectural projects, there exists a steel grate tailored to your needs. Each type boasts distinctive features and advantages, allowing you to select the ideal grating solution precisely suited to your requirements.

How thick is the steel grate?

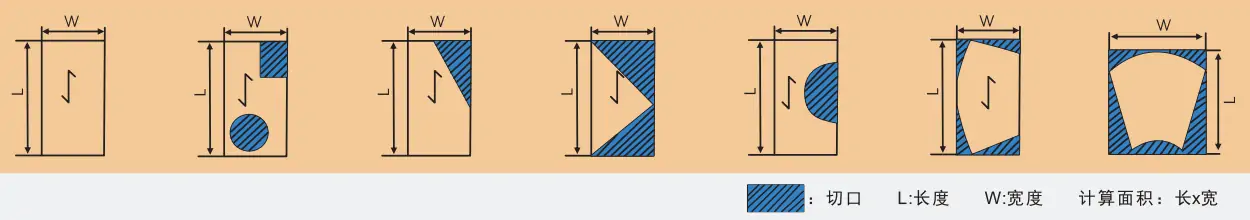

The thickness of a steel grate can vary depending on its intended use and the specific requirements of the application. Here’s an overview of the typical thickness range for steel grates:

Light-Duty Grates: Light-duty steel grates, often used in pedestrian walkways, landscaping, or decorative applications, typically have a thickness ranging from 1/8 inch to 3/16 inch (about 3.2 mm to 4.8 mm). These thinner grates are sufficient for supporting foot traffic and providing traction while maintaining a lightweight and cost-effective design.

Medium-Duty Grates: Medium-duty steel grates are designed to withstand heavier loads and more frequent use than light-duty grates. They typically have a thickness ranging from 1/4 inch to 3/8 inch (about 6.4 mm to 9.5 mm). These grates are commonly used in industrial settings, drainage systems, and vehicular traffic areas where durability and strength are essential.

Heavy-Duty Grates: Engineered to endure rigorous loads and severe environments, heavy-duty steel grates excel in demanding settings like loading docks, airports, and industrial equipment support. Typically featuring thicker profiles ranging from 1/2 inch to 3/4 inch (about 12.7 mm to 19.1 mm) or even more in some instances, their heightened thickness imparts enhanced strength and stability. This fortification ensures the grates maintain integrity under heavy loads, resisting bending or deformation with resilience.

Custom Thickness: In some cases, steel grates may be custom-made to meet specific requirements for load capacity, durability, or environmental factors. In such instances, the thickness of the grates will be determined based on engineering calculations and project specifications to ensure optimal performance and longevity.

It’s essential to recognize that while the thickness of a steel grate is significant, it’s just one aspect among several to consider when selecting the optimal grating solution. Factors like material composition, mesh size, bar spacing, and surface treatment all wield substantial influence in determining a grate’s suitability for a given application. By familiarizing yourself with typical thickness ranges for steel grates, you empower yourself to make informed decisions, ensuring the chosen grating solution aligns perfectly with your requirements.

Which steel grate is better?

Determining which steel grate is better depends largely on the specific requirements of your project or application. Here are some key factors to consider when evaluating different types of steel grates:

1. Load Capacity: If your project involves supporting heavy loads such as vehicular traffic or heavy machinery, you’ll need a heavy-duty steel grate with a thicker profile to ensure sufficient strength and stability.

2. Durability: Durability is paramount when selecting a steel grate, especially concerning the environmental conditions it will face. In outdoor settings or areas prone to high moisture or corrosive elements, opting for a corrosion-resistant steel grate like stainless steel or galvanized steel is advisable. These materials offer superior resistance to rust and corrosion, ensuring long-term performance even in challenging environments. By prioritizing durability and choosing the appropriate material, you can enhance the longevity and reliability of your steel grate investment.

3. Safety: Safety is paramount, especially in areas where slips, trips, and falls are a concern. Choose a steel grate with appropriate traction features such as serrated edges or anti-slip coatings to minimize the risk of accidents.

4. Cost-Effectiveness: While heavier and thicker steel grates may offer superior strength and durability, they often come at a higher cost. Consider your budget constraints and weigh the upfront cost against the long-term benefits of investing in a more durable grate that requires less maintenance and replacement over time.

5. Application Specifics: Steel grates come in various types, each designed for specific applications like pedestrian walkways, drainage systems, industrial flooring, or architectural features. It’s crucial to evaluate the unique requirements of your project meticulously. By selecting a steel grate specifically engineered to meet those needs, you ensure optimal performance and longevity. Whether it’s robustness for industrial flooring or aesthetics for architectural features, choosing the right steel grate enhances functionality and enhances the overall success of your project.

Determining which steel grate is superior isn’t a one-size-fits-all scenario. It hinges on a blend of factors like load capacity, durability, safety, cost-effectiveness, and application specifics. Through meticulous consideration of these aspects and selecting the steel grate that best fits your project requirements, you can guarantee optimal performance and long-term effectiveness. Remember, it’s the synergy of these factors that ensures the chosen grate aligns seamlessly with your project goals, fostering success and longevity.