Hexagonal wire mesh is a versatile and widely used material in various industries, including agriculture, construction, and landscaping. If you are planning a project that requires hexagonal wire mesh, it is important to understand the factors that influence its price. This price guide will help you make informed decisions and find the best deal for your project.

Table of Contents

ToggleIntroduction

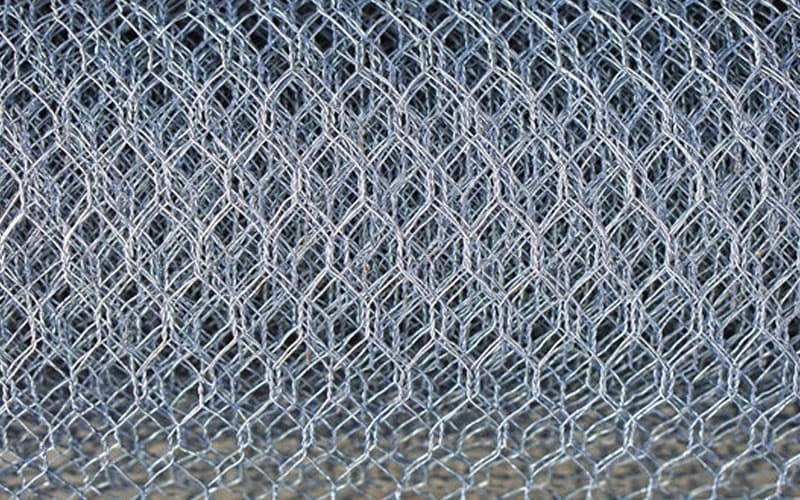

Hexagonal wire mesh, also known as chicken wire or poultry netting, is made of high-quality galvanized or PVC-coated wire. It consists of hexagonal openings that provide excellent strength and flexibility. It is commonly used for fencing, enclosure, and protection purposes.

Understanding the Hexagonal Wire Mesh:

Before discussing the price factors, it is essential to understand the properties and specifications of hexagonal wire mesh. This will help in assessing the quality and suitability of the materials offered by different suppliers.

Factors Influencing Hexagonal Wire Mesh Price

Material Quality:

The quality of the wire used for manufacturing the hexagonal mesh plays a significant role in determining its price. High-quality galvanized or PVC-coated wire will offer better durability and corrosion resistance.

Wire Diameter:

The thickness of the wire used in hexagonal mesh is an important consideration. Thicker wire offers greater strength and stability, but it tends to be more expensive. Choose the wire diameter that suits your project requirements while considering the budget.

Mesh Size:

The size of the hexagonal openings in the mesh affects the price. Smaller mesh sizes require more wire and, therefore, may cost more. Determine the suitable mesh size based on the intended application and the level of protection or containment required.

Coating Type:

Hexagonal wire mesh can have different types of coatings, such as galvanized or PVC. The coating enhances the durability and aesthetics of the mesh. Galvanized wire mesh tends to be more affordable compared to PVC-coated mesh due to the additional coating material cost.

Quantity:

The quantity of hexagonal wire mesh needed for your project will influence the price. Bulk orders usually come with discounts, so it is advisable to calculate the required quantity accurately to take advantage of such cost-saving opportunities.

Order Customization:

If you require customized hexagonal wire mesh with specific dimensions, coatings, or features, it may come at a higher price. Custom orders involve additional manufacturing and processing costs.

Evaluating the Importance of Each Factor

Consider your project requirements and prioritize the factors that are most critical. For example, if corrosion resistance is a priority, investing in high-quality galvanized or PVC-coated wire may be justified, even if it means a slightly higher price.

Price Comparison

To find the right hexagonal mesh price, compare quotes from different suppliers. Let them offer competitive prices while maintaining quality standards. Find reputable suppliers. Also, be sure to consider factors like shipping costs and delivery times when evaluating different quotes.

Tips for Finding the Best Hexagonal Wire Mesh Price

Market Research:

Before purchasing hexagonal nets, conduct market research to understand the product price ranges and related information of different suppliers.

Multiple Supplier Comparison:

Contact multiple suppliers to get quotes and compare price, quality, and service from different suppliers. Choose suppliers with a good reputation, high product quality, and reasonable prices.

Buy in Bulk:

If you need a large quantity of hexagonal mesh, try buying in bulk and you can usually get a better price.

Bargaining:

Conduct haggling negotiations with suppliers to try to get a lower price. Demonstrating your knowledge of market prices can help you negotiate better.

Consider Delivery and After-sales Service:

In addition to price, also consider the supplier’s delivery and after-sales service. Choose a supplier that offers fast, reliable delivery and can provide effective after-sales support.

Assessing the Value

Durability and Strength:

Higher quality materials provide better durability and strength, reducing the need for frequent replacement or repairs, extending the life of the mesh, and reducing maintenance costs.

Application Suitability:

Make sure the hex mesh you choose is suitable for your specific application. An inappropriate mesh can lead to poor performance and potential project failure.

Warranty and Customer Support:

Consider vendors that offer warranties and reliable customer support. This ensures that help is available if any issues arise with the product.

Hexagonal Wire Mesh Price Trends:

Past, Present, and Future: Keep an eye on the price trends for hexagonal wire mesh. Historical data and market analysis can provide insight into future price fluctuations.

Budgeting for Your Project

Determining Quantity and Size:

Calculate the required quantity and size of the hexagonal wire mesh accurately based on your project requirements.

Allocating Funds:

Once you have an estimate of the total cost, allocate funds accordingly. Set aside a reasonable budget that covers the cost of the mesh along with other project expenses.

Contingency Planning:

Prepare for unexpected costs by factoring in a contingency budget. This will help you address any unforeseen expenses during the project.

By understanding the different pricing factors and comparing quotes from different suppliers, you can find the best hexagonal mesh price for your project without compromising on quality.