When it comes to industrial filtration, selecting the right wire mesh filters isn’t just a technical decision—it’s a critical one that can impact your efficiency, product quality, and operational safety. Whether you’re filtering air, liquids, or gases, the aperture size and mesh material you choose will determine how effectively the filter performs.

In this guide, we’ll break down what you need to know about wire mesh filters—from understanding mesh specifications to choosing the right materials for your industry.

Table of Contents

ToggleWhat Is Wire Mesh Filters and Why Does It Matter?

A wire mesh filter is a woven or welded grid of wires used to separate particles from a fluid or gas. It acts as a barrier that allows smaller elements to pass through while capturing larger ones.

These filters are widely used in:

-

Water treatment plants

-

Food and beverage processing

-

Petrochemical facilities

-

Pharmaceutical manufacturing

-

HVAC systems

Choosing the correct filter ensures smooth operations, minimizes downtime, and extends the life of your machinery.

Understanding Aperture: The Key to Filter Performance

The aperture—also known as mesh size—refers to the size of the openings between the wires. It is usually expressed in one of two ways:

-

Mesh count: The number of openings per linear inch

-

Micron rating: The actual size of the opening in micrometers

For example:

-

A 100 mesh filter means 100 openings per inch (approximately 150 microns)

-

A 200 mesh filter has finer openings (~74 microns), suitable for finer filtration

Why Aperture Matters

The size of the particles you need to filter determines the ideal mesh size. Oversized apertures let contaminants through, while undersized ones may clog quickly or reduce flow efficiency.

Common Filter Mesh Materials and Their Benefits

Different industrial applications require different filter mesh materials. Here’s a breakdown of the most commonly used options:

1. Stainless Steel Wire Mesh (304/316)

-

High tensile strength

-

Excellent corrosion resistance

-

Suitable for extreme temperatures

-

Ideal for chemical, marine, and food-grade applications

2. Brass Wire Mesh

-

Good conductivity and ductility

-

Used in filtration of non-corrosive substances

-

Common in decorative and light industrial settings

3. Nylon and Polyester Mesh

-

Lightweight and flexible

-

Suitable for low-pressure environments

-

Often used in food processing or laboratory filtration

4. High-Performance Alloys (Monel, Hastelloy)

-

Superior resistance to heat and chemicals

-

Designed for aggressive environments like acid filtration or high-pressure gas systems

Choosing the Right Filter Mesh for Your Industry

Here are a few key questions to ask before choosing your wire mesh filter:

-

What is the medium being filtered? (e.g., water, oil, gas)

-

What is the temperature range? (some materials deform under heat)

-

Is corrosion resistance required? (especially important in chemical processing)

-

What particle size needs to be filtered out?

-

How often will the filter be cleaned or replaced?

Every application is different. For instance, a food-grade filter must not only remove particles but also comply with safety regulations, while a gas filter may need to withstand high pressure.

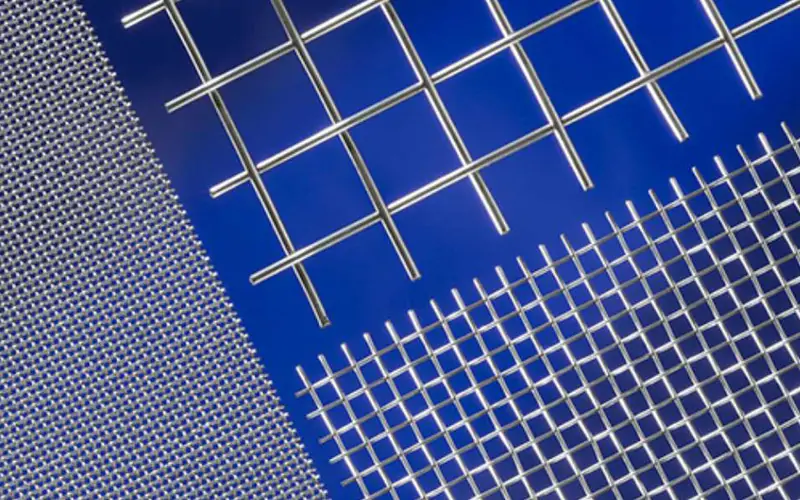

Woven vs. Welded vs. Sintered: Which Filter Type Is Best?

Woven Wire Mesh

-

Flexible and customizable

-

Offers precision in aperture control

-

Best for fine filtration applications

Welded Wire Mesh

-

Rigid and strong

-

Retains shape under pressure

-

Great for structural support in filtration units

Sintered Wire Mesh

-

Layers of mesh fused together

-

Offers high durability and backwashing capability

-

Preferred in pharmaceutical and hydraulic systems

Final Checklist: What to Confirm Before Buying

Before placing an order for your industrial filter mesh, make sure you:

-

Confirm the mesh size and material specs

-

Request product datasheets or test reports

-

Verify chemical compatibility and temperature limits

-

Choose a trusted wire mesh manufacturer with customization options

-

Ask about lead time, especially for bulk or custom orders

Conclusion: A Smart Filter Choice Starts with Smart Selection

A well-chosen wire mesh filter can boost productivity, reduce contamination risks, and prolong equipment life. When evaluating options, always consider aperture size, material durability, and application-specific needs.

Whether you’re managing a water treatment facility or operating a food-grade plant, understanding the basics of filter mesh selection puts you ahead of the curve.