304 & 316 materials Stainless Steel Grating for Corrosive Projects

304 and 316 stainless steel grating stand out as premium choices for projects exposed to harsh corrosive conditions. With superior corrosion resistance, enhanced by high chromium and nickel contents in 304, and further improved with molybdenum addition in 316, these gratings ensure durability and structural integrity in diverse industrial settings. Both materials offer robust construction, optimal airflow, and ease of maintenance, making them ideal solutions for marine, chemical, food processing, and other high-risk corrosion applications.

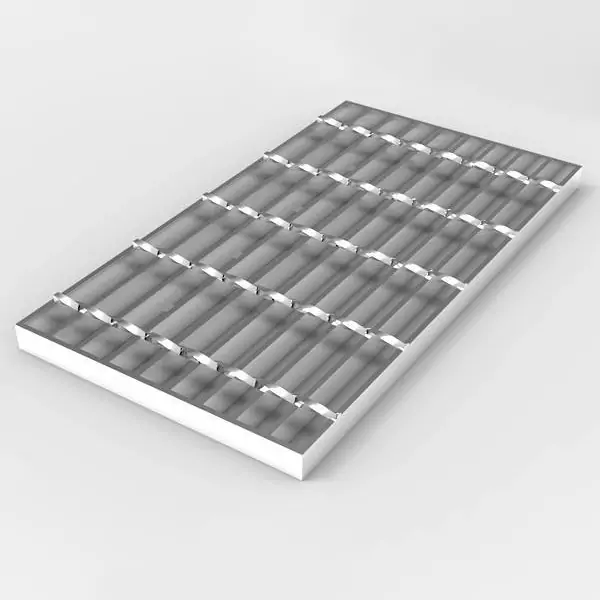

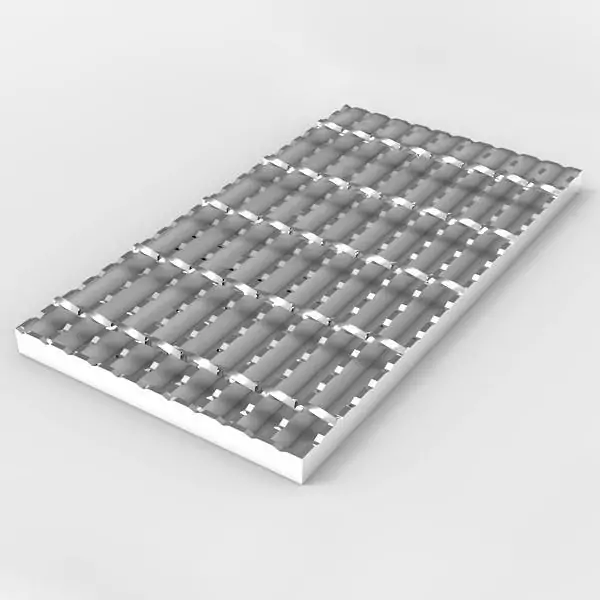

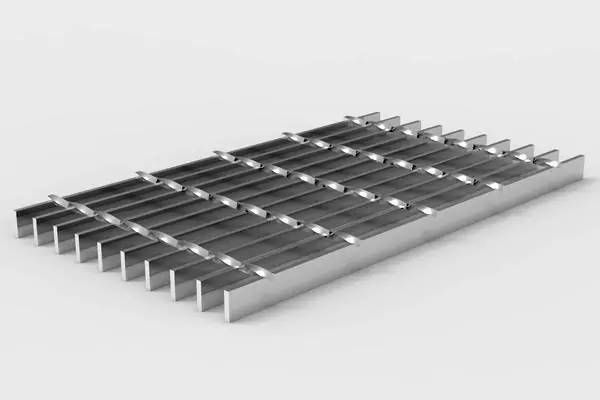

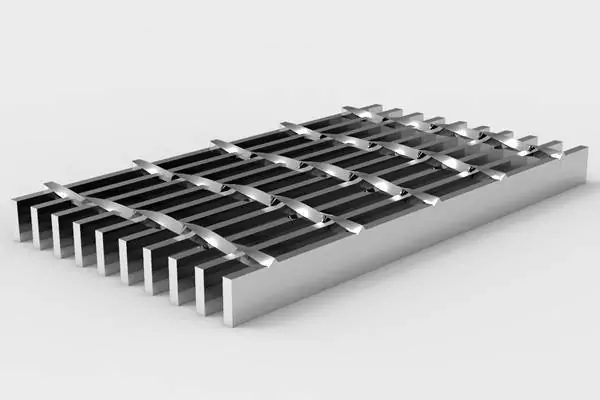

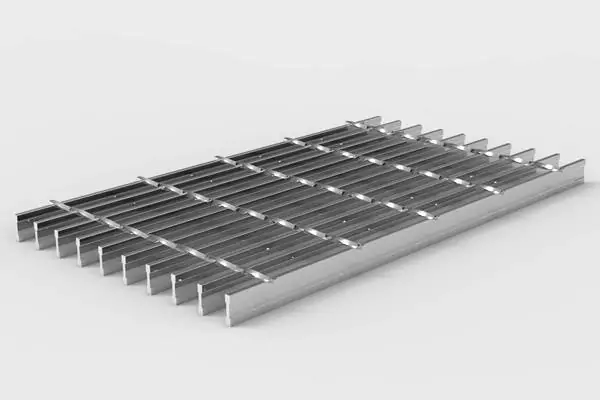

❖ Both in Smooth or serrated surface.

❖ 304 or 316 grade for choice.

❖ Wide range of bearing bar sizes and pitches.

❖ Special discount for large orders.

❖ Project reference can be supplied for your bid.

❖ ISO Certificated factory.

❖ CAD or 3D drawing can be supplied for your design and construction.

Product Videos

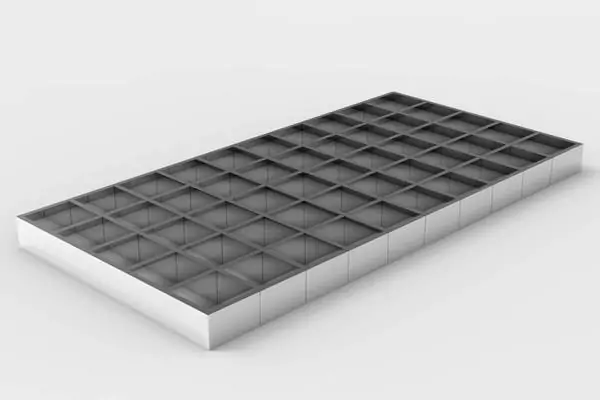

Bearing Bar Type

Dimensions

- Material: stainless steel 304, 304L, 316, 316L.

- Finish: mill finish, commercial clean and electro polished.

- Bearing bar spacing: ranging from 1-3/16″ to 11/16″.

- Cross bar spacing: 2″ or 4″ on center.

| Type | Description | Tensile Strength | Yield |

|---|---|---|---|

| 304 | Good corrosion resistance, high tensile strength, excellent for chemical processing, food industries, power plants and waste water treatment. Used in high temperature applications | 75,000 psi (min.) | 30,000 psi (min.) |

| 316 | Better corrosion and pitting resistance than type 304, good heat resistance, used in chemical, pulp and paper processing, marine environments, textile equipment, petroleum refining. | 75,000 psi (min.) | 30,000 psi (min.) |

| Metric Legend | Imperial Legend |

|---|---|

| U = Safe Uniform Load (kPa) C = Safe Concentrated Load (kN/meter of grating width) D = Deflection (mm) | U = Safe Uniform Load (lbs./ft2) C = Safe Concentrated Load (lbs./foot of grating width) D = Deflection (inches) |

| Stainless Steel Grade | Load/Deflection | Multiply Carbon Steel Load Tables By: | Based on Maximum Allowable Fiber Stress |

|---|---|---|---|

| 304Stainless Steel | U | 1.111 | 20,000 P.S.I. (137.9 MPa) |

| C | 1.111 | ||

| D | 1.151 | ||

| 304LStainless Steel | U | 0.917 | 16,500 P.S.I. (113.8 MPa) |

| C | 0.917 | ||

| D | 0.949 | ||

| 316Stainless Steel | U | 1.111 | 20,000 P.S.I. (137.9 MPa) |

| C | 1.111 | ||

| D | 1.151 | ||

| 316LStainless Steel | U | 0.917 | 16,500 P.S.I. (113.8 MPa) |

| C | 0.917 | ||

| D | 0.949 |

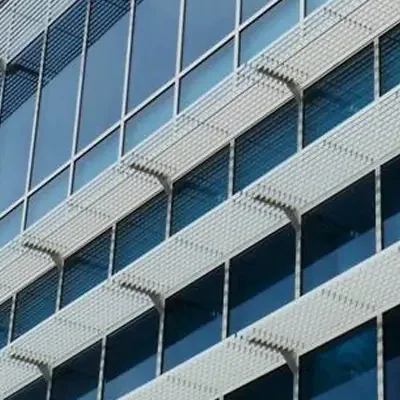

Product Application

It can provide durable grating solution for corrosive resistance and minimum carbide precipitation are important considerations, typical applications include stairs and platforms for chemical production and storage, food processing and water and waste water treatment plant.